What Is A Fulfillment Center? A Complete Guide (2025)

What is E-commerce Fulfillment? An Introduction for Growing Businesses

Understanding E-commerce Fulfillment

As an e-commerce business owner, you may find yourself overwhelmed with the challenges of packing and shipping orders. The excitement of growing sales can quickly turn into stress when you realize that fulfilling those orders is not as simple as it seems. The process of getting a product into the hands of your customers involves multiple steps, and without a solid fulfillment strategy, your growth may stall.

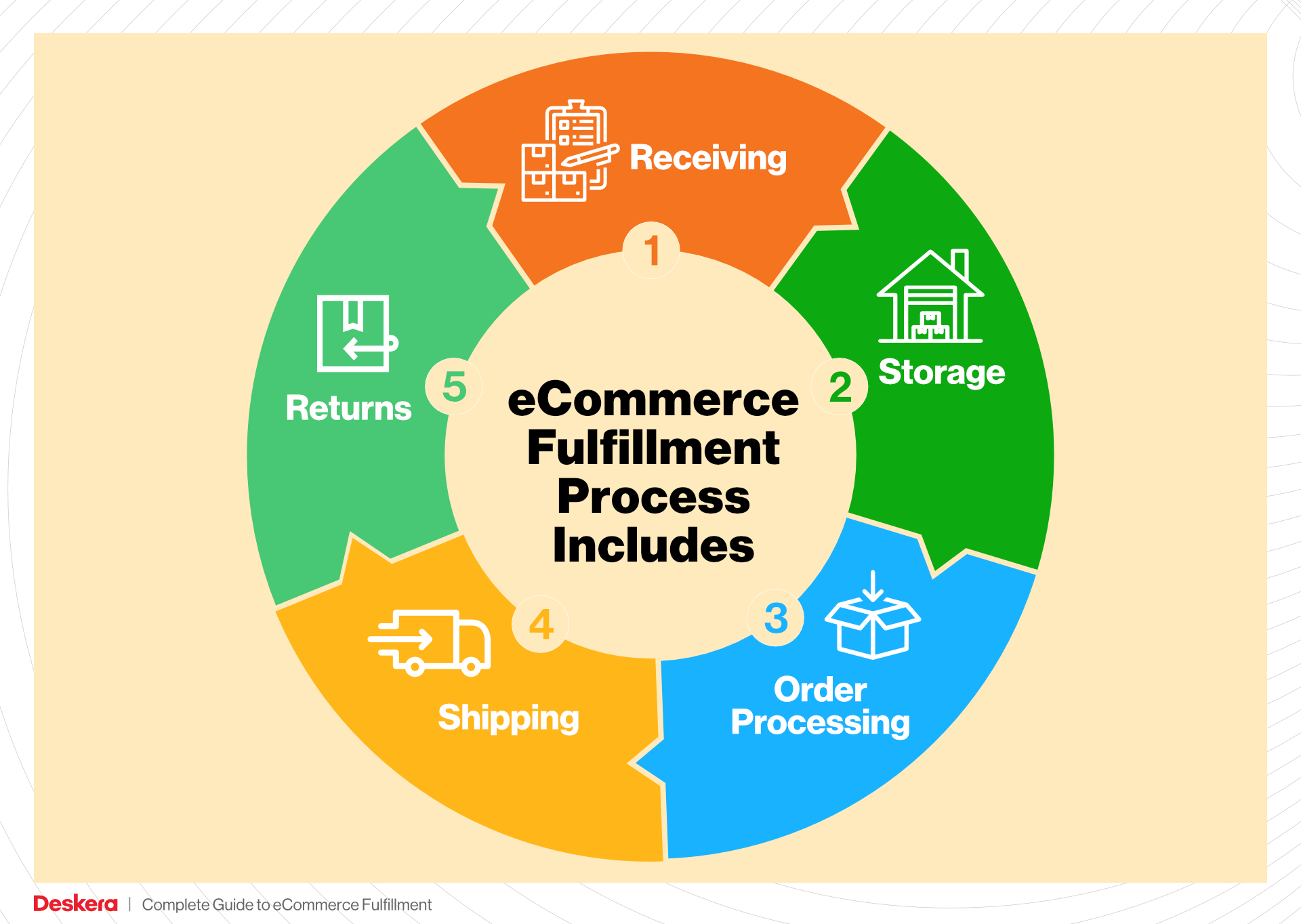

So, what exactly is fulfillment? In its simplest form, e-commerce fulfillment is the entire process of receiving, processing, and delivering orders to customers. This encompasses everything from inventory management and order processing to packaging and shipping. For growing businesses, mastering this process is crucial for maintaining customer satisfaction and ensuring repeat sales.

In this guide, we will explore various fulfillment models that can help streamline your operations. You’ll learn about Third-Party Logistics (3PL), Fulfillment by Amazon (FBA), and other options that can alleviate the burden of managing logistics on your own. Understanding these models will allow you to choose the one that best aligns with your business needs.

We will also cover the core services involved in the fulfillment process, including inventory management, order processing, packing, shipping, and handling returns. Each of these components plays a vital role in ensuring that your customers receive their orders accurately and on time.

Choosing the right fulfillment partner is another critical decision that can impact your business’s efficiency and customer satisfaction. We will provide practical advice on how to evaluate potential partners, what questions to ask, and what factors to consider, such as scalability, technology integration, and customer service.

Finally, we will discuss pricing considerations and how to manage costs effectively while maintaining high service levels. Understanding the financial implications of different fulfillment strategies will empower you to make informed decisions that support your growth.

The goal of this guide is to equip you with the knowledge and tools to make smart, strategic decisions about your logistics. By optimizing your fulfillment process, you can focus on what you do best: growing your business and delighting your customers.

What You’ll Learn In This Guide

- What is E-commerce Fulfillment? An Introduction for Growing Businesses

- The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

- Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

- A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

- Core Services Offered by Fulfillment Centers

- How to Choose a Fulfillment Partner: A 6-Point Checklist

- Understanding Fulfillment Pricing: A Breakdown of Common Fees

- Frequently Asked Questions (FAQs) about Fulfillment

- Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

- Important Disclaimer

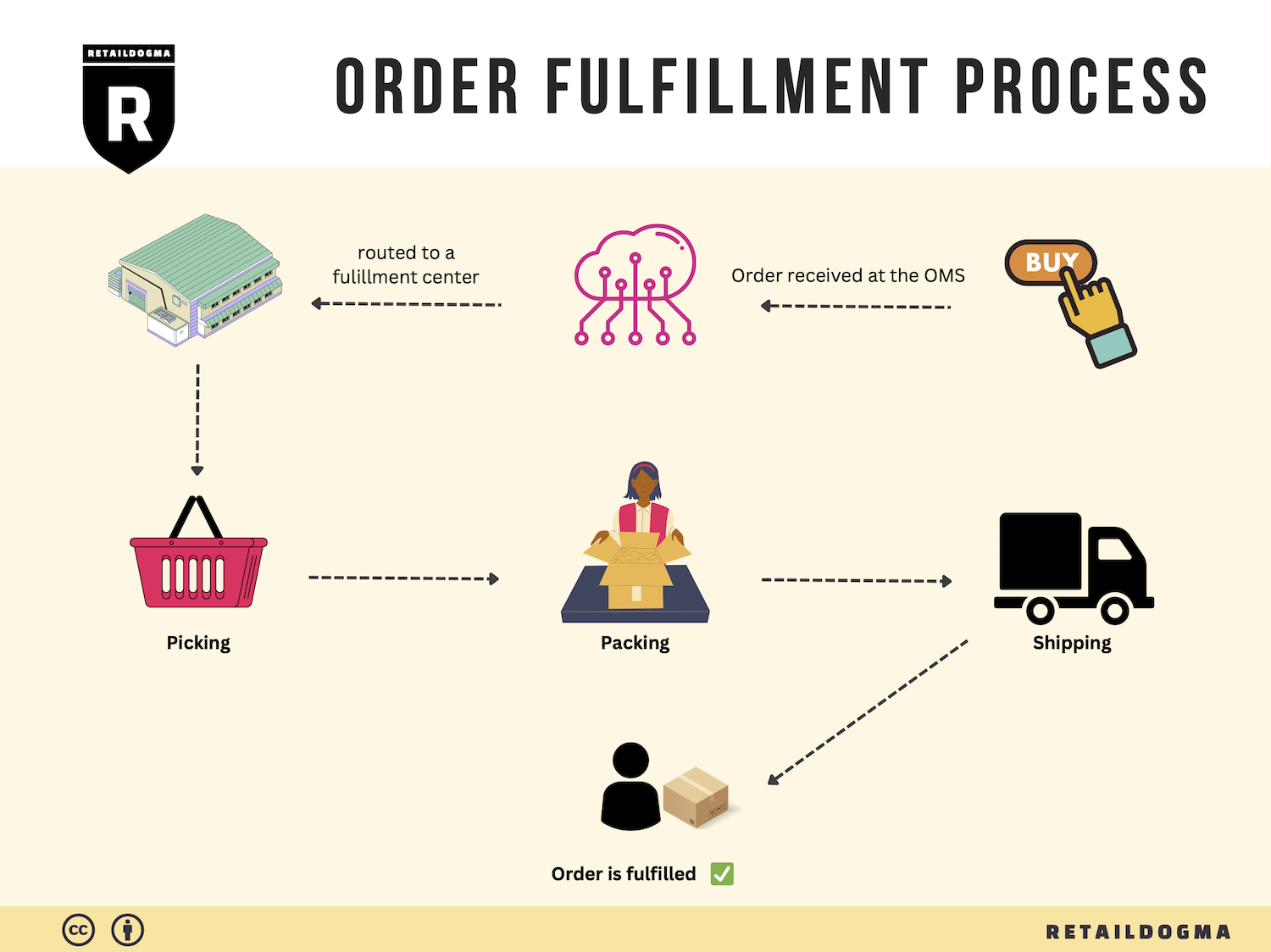

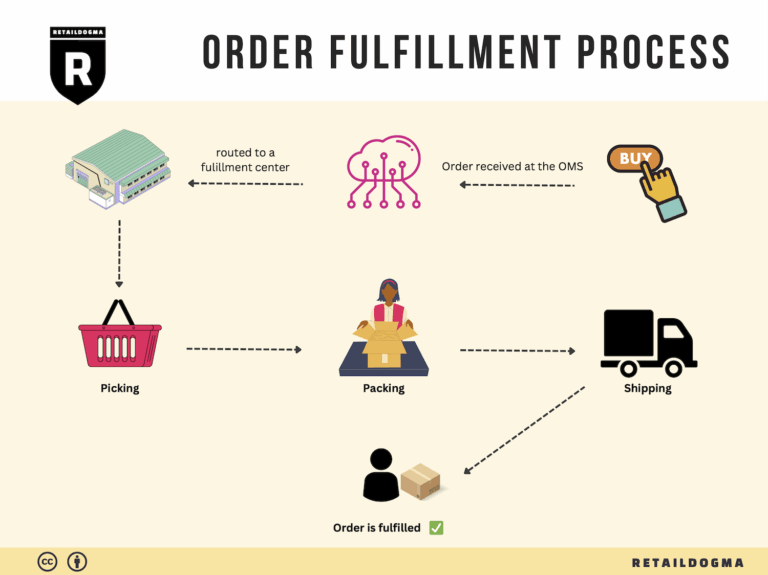

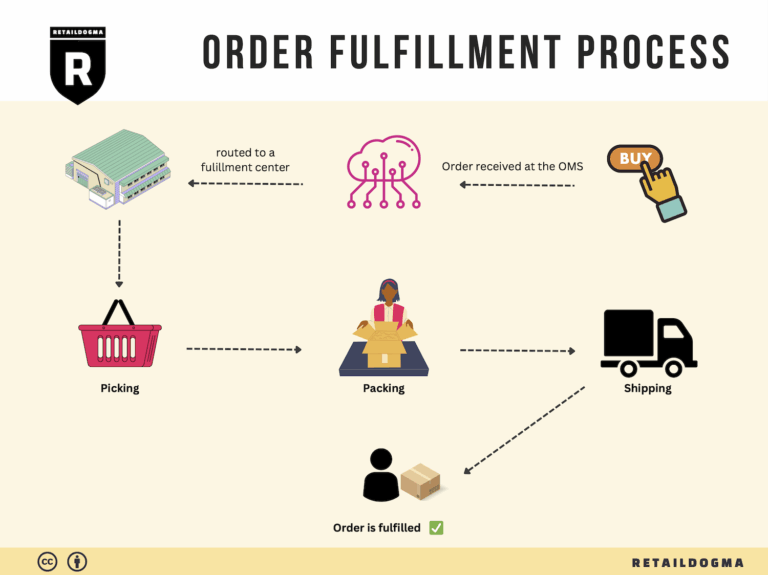

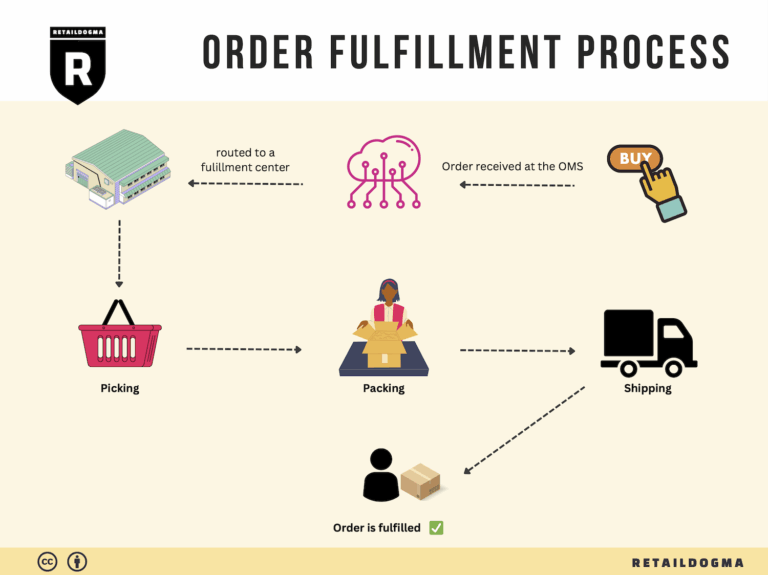

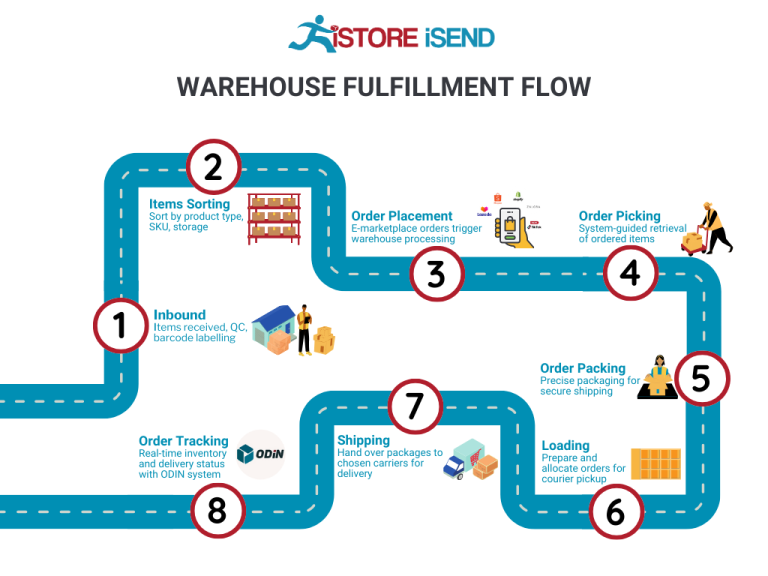

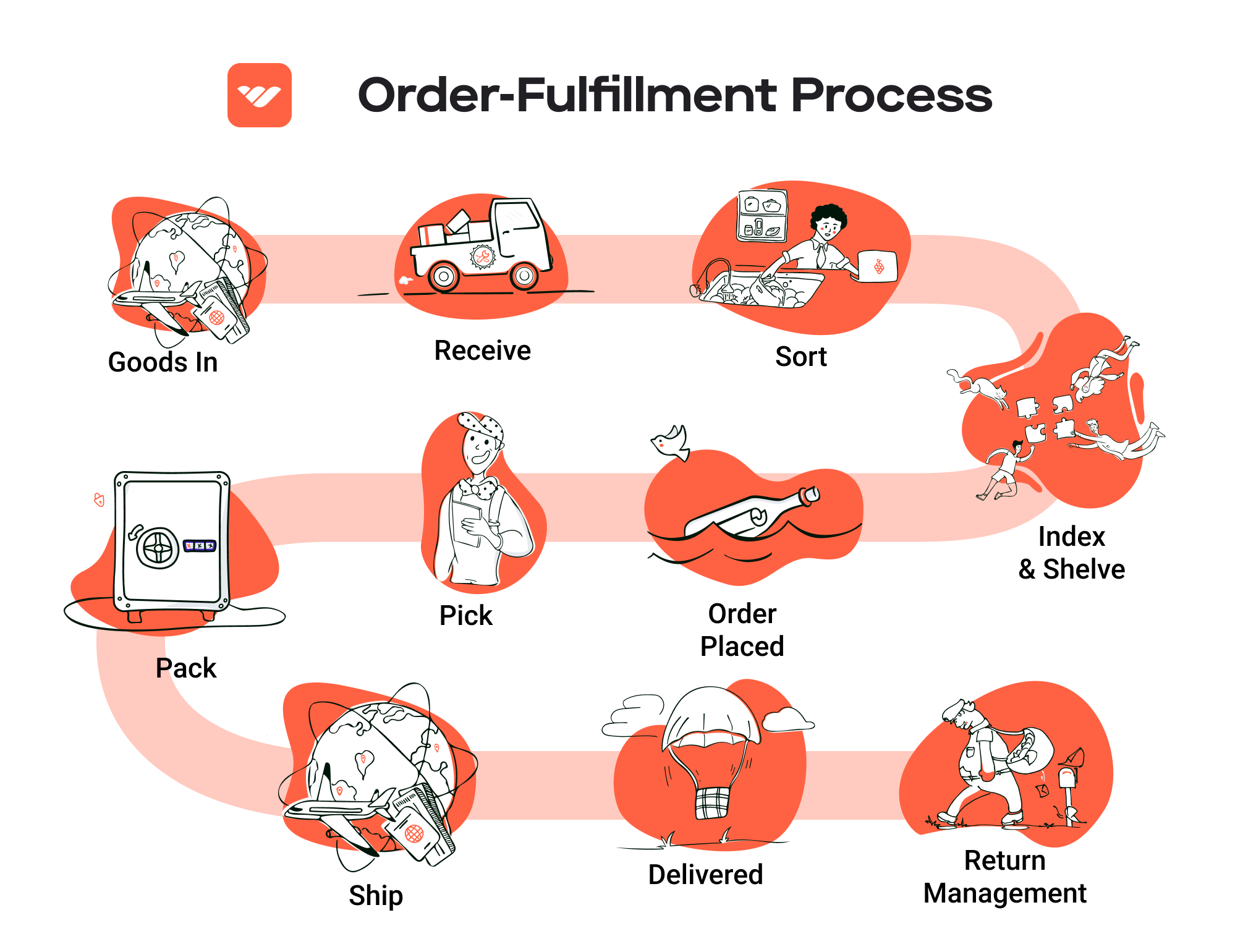

The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

1. Receiving Inventory

The first step in the order fulfillment process is receiving inventory. This involves accepting shipments from suppliers and verifying that the products match what was ordered. Each item is checked against purchase orders to ensure accuracy in quantity and quality. Key terms like SKU (Stock Keeping Unit) are crucial here, as they help in identifying and managing inventory efficiently.

This step is vital because it sets the foundation for all subsequent processes. If there are discrepancies—such as missing items or damaged goods—these need to be addressed immediately to avoid delays later on. Additionally, accurate inventory management ensures that you have the right products available to meet customer demand, minimizing the risk of stockouts that can lead to lost sales.

2. Warehouse Storage

Once inventory is received and verified, the next step is warehouse storage. Products are organized and stored in designated locations within the warehouse, often utilizing a systematic approach such as bin locations or shelf labels for easy retrieval. This organization is typically guided by the principles of ABC analysis, which categorizes inventory based on its importance and turnover rate.

Effective warehouse storage is essential for operational efficiency. A well-organized warehouse reduces the time needed to locate items, thereby speeding up the entire fulfillment process. Additionally, maintaining a clean and orderly storage area can prevent accidents and damage, which can lead to additional costs. Proper storage practices also facilitate inventory audits and ensure that stock levels are accurately reflected in your inventory management system.

3. Order Picking

After an order is placed by a customer, the next step is order picking. This involves selecting the items from their storage locations based on the order details. Companies often use pick lists, which are documents or digital lists that outline the items to be collected, along with their respective SKUs and locations.

Order picking is a critical phase because it directly impacts order accuracy and customer satisfaction. Errors in this step can lead to incorrect shipments, resulting in returns and dissatisfied customers. To enhance efficiency, businesses may implement various picking methods, such as batch picking (collecting multiple orders simultaneously) or zone picking (assigning specific areas of the warehouse to different pickers). These strategies can significantly reduce picking time and increase throughput.

4. Order Packing

Once the items are picked, they move to the order packing stage. Here, products are carefully packed into shipping boxes, often using branded packaging materials that reflect the company’s image. This stage also involves including necessary documentation, such as packing slips or invoices, and using protective materials to prevent damage during transit.

Packing is crucial as it affects both the presentation of the product and its safety during shipping. Proper packing helps to minimize the risk of returns due to damaged goods and enhances the unboxing experience for customers, which can lead to repeat business. Additionally, businesses must consider dimensional weight pricing in shipping costs, which means the size of the package can affect shipping fees, making efficient packing even more important.

5. Shipping & Delivery

The final step in the order fulfillment process is shipping and delivery. This stage involves choosing the appropriate shipping method and carrier, preparing the shipment for dispatch, and generating tracking information for customers. Key terms associated with this step include shipping labels and carrier selection.

Shipping is vital for ensuring that products reach customers in a timely manner. Customers today expect fast and reliable delivery, making it essential for businesses to communicate accurate delivery timelines. Delays in shipping can lead to frustration and damage to the brand’s reputation. Furthermore, offering various shipping options—such as standard, expedited, or same-day delivery—can enhance customer satisfaction and cater to different customer needs.

In conclusion, mastering the order fulfillment process is crucial for e-commerce businesses aiming to scale effectively. Each step—from receiving inventory to shipping and delivery—plays a significant role in ensuring customer satisfaction and operational efficiency. By implementing best practices in each stage, businesses can optimize their fulfillment operations and drive growth.

Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

Comparison of Fulfillment Models

| Model | Who Handles Inventory | Best For (Business Stage) | Key Advantage | Key Disadvantage |

|---|---|---|---|---|

| In-House Fulfillment | The business itself | Startups and small businesses | Full control over inventory and processes | Limited scalability and increased operational burden |

| Third-Party Logistics (3PL) | A contracted logistics provider | Growing businesses with increasing order volume | Expertise in logistics and cost reduction | Less control over shipping and inventory management |

| Dropshipping | The supplier | New businesses or those testing markets | Low startup costs and minimal risk | Limited control over product quality and fulfillment speed |

In-House Fulfillment

In-house fulfillment involves managing the entire process of order fulfillment within your own business premises. This means you handle everything from inventory management to packaging and shipping. This model is particularly effective for small businesses or startups that have a manageable number of orders (typically less than 100 per month) and can easily oversee all aspects of fulfillment. The primary advantage of in-house fulfillment is the complete control it offers over inventory management, branding, and customer service. You can customize packaging, ensure quality checks, and directly address customer inquiries, which can significantly enhance customer satisfaction and brand loyalty.

However, in-house fulfillment comes with its challenges. As your order volume grows, you may find it increasingly difficult to manage all aspects of fulfillment efficiently. This can lead to higher labor costs, potential errors in order processing, and limitations in storage capacity. Additionally, scaling your operations may require significant investment in infrastructure, technology, and human resources, which can be a daunting task for small businesses. Hence, while in-house fulfillment provides control and customization, it may not be sustainable as your business expands.

Third-Party Logistics (3PL)

Third-party logistics (3PL) involves outsourcing your fulfillment operations to a specialized logistics provider. This model is ideal for growing businesses that experience fluctuating order volumes but do not have the infrastructure or resources to manage fulfillment internally. A 3PL provider takes care of storage, inventory management, order processing, shipping, and even returns. By leveraging the expertise of a 3PL, businesses can optimize their supply chain, reduce operational costs, and scale more effectively.

One of the key advantages of using a 3PL is the ability to focus on core business activities, such as marketing and product development, while leaving the logistics to professionals. This can lead to improved efficiency and faster order fulfillment times, which are critical for maintaining customer satisfaction in today’s competitive e-commerce landscape. However, a significant downside is the loss of control over certain aspects of the fulfillment process. If the 3PL provider fails to meet service expectations, it can negatively impact your brand’s reputation and customer experience. Therefore, it is crucial to choose a reliable 3PL partner and establish clear communication and service level agreements to mitigate these risks.

Dropshipping

Dropshipping is a fulfillment model that allows e-commerce businesses to sell products without holding any inventory. Instead, when a customer places an order, the business purchases the item from a third-party supplier, who then ships it directly to the customer. This model is particularly appealing to entrepreneurs starting a new business or those testing new products or markets, as it requires minimal upfront investment and eliminates the risks associated with unsold inventory.

The primary advantage of dropshipping is its low operational costs. You do not need to invest in warehousing, inventory, or shipping logistics, which significantly reduces the financial risk. Additionally, dropshipping allows for a diverse product range, as you can offer products from various suppliers without the need for storage space. However, dropshipping also comes with its share of disadvantages. The most significant is the lack of control over product quality and shipping times, which can lead to customer dissatisfaction if issues arise. Furthermore, since you are reliant on suppliers for inventory management, any delays or mistakes on their part can directly affect your business’s reputation. Thus, while dropshipping offers a low-risk entry into e-commerce, it requires careful supplier selection and management to ensure a positive customer experience.

Conclusion

Choosing the right fulfillment model is a critical decision for any e-commerce business owner. Each model—whether in-house fulfillment, 3PL, or dropshipping—comes with its unique set of advantages and disadvantages. The best choice will depend on your business’s size, stage, product type, and growth aspirations. As you consider these options, reflect on your operational capabilities, financial resources, and long-term goals to select a fulfillment strategy that aligns with your vision for success.

A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

What is Fulfillment by Amazon (FBA)?

Fulfillment by Amazon (FBA) is a service offered by Amazon that allows e-commerce sellers to store their products in Amazon’s fulfillment centers. Once a customer places an order for a seller’s product, Amazon takes care of the storage, packaging, and shipping. This service not only streamlines the logistics process for sellers but also leverages Amazon’s extensive logistics network to deliver products quickly and efficiently.

When a seller enrolls in FBA, they send their inventory to Amazon’s warehouses, where it is stored until sold. Amazon handles the entire order fulfillment process, including customer service and returns. This means that sellers can focus on growing their business while benefiting from Amazon’s infrastructure and customer base.

How FBA Works

-

Inventory Storage: Sellers send their products to Amazon’s fulfillment centers, where they are stored until sold. Sellers can track their inventory through the Amazon Seller Central dashboard.

-

Order Processing: When a customer orders a product, Amazon’s system automatically picks, packs, and ships the item from its nearest fulfillment center.

-

Customer Service: Amazon manages customer inquiries and returns for FBA products. This includes handling refunds, processing returns, and answering customer questions.

-

Shipping and Handling: FBA products are eligible for Amazon Prime and other shipping options, allowing sellers to offer fast and free shipping to customers.

-

Returns Management: Amazon provides a streamlined process for returns, making it easier for customers to send items back. This can enhance customer satisfaction and trust in the seller’s brand.

Pros of Using FBA

1. Prime Eligibility

One of the biggest advantages of FBA is that products become eligible for Amazon Prime, allowing sellers to tap into a vast customer base that values fast shipping. Prime members often prefer products that offer Prime shipping, which can significantly increase a seller’s visibility and sales.

2. Customer Trust

Using FBA can enhance customer trust. Since Amazon is known for its reliable service and customer support, customers are more likely to purchase from sellers using FBA, knowing that they will receive their orders promptly and have access to Amazon’s return policy.

3. Multi-Channel Fulfillment

FBA is not limited to just Amazon sales. Sellers can utilize Amazon’s fulfillment services for orders placed through other channels, such as their own website or other marketplaces. This multi-channel fulfillment capability allows for greater flexibility and can simplify logistics management.

4. Simplified Logistics

FBA streamlines the logistics process, allowing sellers to avoid the complexities of managing inventory, packing, and shipping. This can free up valuable time and resources, enabling sellers to focus on marketing and product development.

5. Scalable Operations

As businesses grow, FBA can easily scale with them. Sellers can increase their inventory and sales volume without needing to invest in their own storage and logistics infrastructure.

Cons of Using FBA

1. High Fees

FBA comes with various fees, including storage fees for inventory stored in Amazon’s warehouses and fulfillment fees for each unit sold. These costs can add up, particularly for sellers with lower profit margins, which can impact overall profitability.

2. Strict Inventory Rules

Amazon has specific guidelines and policies regarding inventory management. Sellers must ensure that their products comply with these rules, which can be challenging, especially for new sellers. Failure to adhere to these guidelines can result in penalties or account suspension.

3. Commingling Risks

When using FBA, sellers’ inventory may be commingled with that of other sellers. This means that when a customer orders a product, they could receive a product from another seller. If that product is damaged or of lower quality, it could reflect poorly on the original seller’s reputation.

4. Loss of Control

By outsourcing fulfillment to Amazon, sellers lose some control over the customer experience, including packaging and shipping times. If there are delays or issues with Amazon’s fulfillment process, it can negatively impact the seller’s brand and customer satisfaction.

5. Limited Branding Opportunities

FBA requires sellers to use Amazon’s packaging and branding for their products, which can limit opportunities for personalized branding. This can be a disadvantage for sellers looking to establish a strong brand identity.

Who is FBA Best For?

FBA is an excellent option for:

-

Small to Medium-Sized Businesses: Sellers looking to scale their operations without investing heavily in logistics can benefit from FBA’s simplified fulfillment process.

-

New Sellers: Entrepreneurs who are just starting their e-commerce journey can leverage Amazon’s established infrastructure and customer trust to gain traction quickly.

-

Businesses with High Sales Volume: Sellers who expect to sell a large volume of products can benefit from the economies of scale that FBA offers, as the service can reduce shipping costs.

-

Multi-Channel Sellers: Businesses that sell across multiple platforms can streamline their logistics by using FBA for all orders, ensuring consistent fulfillment regardless of where the sale occurs.

-

Sellers of Non-Seasonal Products: If your products have consistent demand throughout the year, FBA can provide reliable fulfillment, as opposed to seasonal products that may lead to fluctuating inventory levels and storage fees.

In conclusion, while FBA offers numerous benefits, such as Prime eligibility and simplified logistics, it is essential for sellers to carefully consider the associated fees and potential downsides. Assessing your business model and growth aspirations will help determine whether FBA is the right fit for your e-commerce strategy.

Core Services Offered by Fulfillment Centers

Inventory Management & Warehousing

Inventory management and warehousing form the backbone of any fulfillment operation. Fulfillment centers offer sophisticated inventory management systems that allow e-commerce businesses to track their stock levels in real-time. This includes monitoring which products are available, forecasting demand, and managing reorders to prevent stockouts.

Benefits:

1. Optimized Stock Levels: By maintaining accurate inventory records, e-commerce businesses can avoid overstocking or understocking, leading to improved cash flow and reduced holding costs.

2. Space Efficiency: Utilizing a fulfillment center means businesses can free up their own storage space, which can be repurposed for other operational needs or customer service functions.

3. Scalability: As businesses grow, fulfillment centers can easily adjust their inventory management systems to handle increased volumes without the need for significant capital investment in infrastructure.

Pick and Pack Services

Pick and pack services involve the selection (picking) of items from inventory and packaging (packing) them for shipment. Fulfillment centers employ advanced technology and trained staff to ensure that orders are accurately picked and efficiently packed.

Benefits:

1. Accuracy and Speed: With systems in place that minimize human error, fulfillment centers can process orders quickly and accurately, which is critical for maintaining customer satisfaction.

2. Customized Packaging: Many fulfillment centers offer branded packaging options, allowing e-commerce businesses to enhance their brand visibility and customer experience right from the moment the package is delivered.

3. Streamlined Operations: By outsourcing pick and pack services, businesses can focus on core activities like marketing and product development, rather than the logistics of order fulfillment.

Kitting and Assembly

Kitting and assembly services refer to the process of combining multiple products into a single package or preparing products for sale. This might include assembling items that need to be put together before shipping or creating bundles of related products that can be sold as a single unit.

Benefits:

1. Enhanced Product Offerings: Kitting allows businesses to create unique product offerings, such as gift sets or promotional bundles, which can drive higher sales and improve customer satisfaction.

2. Efficient Order Processing: By pre-assembling products, fulfillment centers can reduce the time spent on individual order fulfillment, leading to faster shipping times and improved turnaround.

3. Inventory Management Flexibility: Businesses can manage inventory more effectively by grouping related items, reducing the complexity of tracking individual items while still offering a wide range of products.

Returns Management (Reverse Logistics)

Returns management, or reverse logistics, is a critical component of the fulfillment process that deals with handling returned products. Fulfillment centers can streamline this process by inspecting, restocking, or properly disposing of returned items.

Benefits:

1. Customer Retention: Efficiently handling returns can enhance customer satisfaction, as a smooth returns process encourages repeat business and fosters customer loyalty.

2. Cost Management: By managing returns effectively, fulfillment centers can minimize losses associated with returned goods, ensuring that items are quickly restocked or reprocessed for resale.

3. Data Insights: Returns data can provide valuable insights into product quality and customer preferences, allowing businesses to make informed decisions about inventory and product offerings.

Conclusion

In summary, fulfillment centers offer a suite of essential services that can significantly enhance the efficiency and effectiveness of e-commerce operations. By leveraging inventory management and warehousing, pick and pack services, kitting and assembly, and returns management, businesses can scale their logistics capabilities, improve customer satisfaction, and ultimately drive growth. As e-commerce continues to evolve, partnering with a capable fulfillment center can provide the competitive edge needed to succeed in a crowded marketplace.

How to Choose a Fulfillment Partner: A 6-Point Checklist

Location & Warehouse Network

The geographical location of your fulfillment partner’s warehouses is critical for ensuring timely delivery to your customers. A partner with strategically placed warehouses can significantly reduce shipping times and costs, enhancing customer satisfaction.

Questions to Ask:

– Where are your warehouses located, and how do these locations align with my target customer base?

– What shipping carriers do you partner with, and how does this influence delivery times and costs?

– Can you provide insights into your average shipping times based on current locations?

Technology & Integrations

In today’s digital landscape, having the right technology is essential for streamlining operations and ensuring seamless order processing. Your fulfillment partner should offer a robust platform that integrates smoothly with your e-commerce systems.

Questions to Ask:

– What order management system (OMS) do you use, and how does it integrate with my current e-commerce platform?

– Do you offer real-time inventory tracking, and how can I access this information?

– What reporting tools are available to monitor fulfillment performance, and can these be customized to meet my needs?

Specializations (e.g., cold storage, oversized items)

Depending on the nature of your products, you may require specific handling capabilities. Whether you deal with perishable goods that need cold storage or oversized items that require special shipping considerations, your fulfillment partner should have the necessary expertise.

Questions to Ask:

– What specializations do you have in terms of product handling (e.g., temperature-sensitive items, fragile goods)?

– How do you ensure compliance with relevant regulations, especially for specialized storage or shipping?

– Can you provide case studies or references from businesses with similar product needs?

Scalability & Capacity

As your business grows, your fulfillment needs will evolve. It’s crucial to partner with a fulfillment provider that can scale alongside your business and accommodate fluctuations in order volume without compromising service quality.

Questions to Ask:

– What is your current capacity, and how do you manage peak seasons or sudden increases in order volume?

– How quickly can you scale operations if my order volume doubles or triples?

– Do you have contingency plans in place for unexpected surges in demand?

Pricing and Contracts

Understanding the pricing structure and contract terms of your fulfillment partner is essential for budgeting and financial planning. Look for transparency in pricing and flexibility in contract terms to avoid unexpected costs.

Questions to Ask:

– Can you provide a detailed breakdown of your pricing model, including any hidden fees?

– What is the minimum contract length, and are there options for flexibility in case my needs change?

– How do you handle pricing adjustments for shipping costs or changes in service levels?

Customer Support & Reviews

Exceptional customer support can make or break your fulfillment experience. A responsive and knowledgeable support team can help resolve issues quickly, ensuring that your operations run smoothly.

Questions to Ask:

– What support channels are available (e.g., phone, email, chat), and what are your typical response times?

– Can you share testimonials or reviews from other clients regarding your customer support?

– How do you handle disputes or issues with orders, and what is your escalation process?

Conclusion

Choosing the right fulfillment partner is a pivotal decision that can significantly impact your e-commerce business’s efficiency and customer satisfaction. By utilizing this checklist and asking the right questions, you can evaluate potential partners effectively and make an informed choice that aligns with your business goals. Remember, the right partner will not only enhance your operational capabilities but also contribute to your overall growth and success in the competitive e-commerce landscape.

Understanding Fulfillment Pricing: A Breakdown of Common Fees

Initial Setup Fees

When partnering with a fulfillment provider, businesses often encounter initial setup fees. These fees cover the costs associated with integrating your e-commerce platform with the fulfillment provider’s systems, onboarding processes, and initial inventory setup. Typically, these fees can range from a few hundred to several thousand dollars, depending on the complexity of your operations and the technology involved.

The calculation of initial setup fees often includes:

- Software Integration: The cost associated with connecting your e-commerce platform (like Shopify or WooCommerce) to the fulfillment center’s systems.

- Inventory Onboarding: Fees for receiving and cataloging your initial inventory.

- Training and Support: Costs related to training your staff on how to use the fulfillment provider’s systems.

It’s essential to clarify these fees upfront, as they can vary widely among providers.

Receiving Fees

Receiving fees are charged when your inventory arrives at the fulfillment center. These fees cover the labor and resources required to unload, inspect, and process incoming shipments. Typically calculated per pallet or per hour of labor, receiving fees can vary significantly based on the volume and complexity of the goods being received.

Factors influencing receiving fees include:

- Volume of Inventory: Higher volumes might attract bulk rates.

- Complexity of Products: Items requiring special handling or inspection may incur additional charges.

- Frequency of Deliveries: Regular deliveries might lead to negotiated rates with your provider.

Understanding how these fees are structured can help you budget effectively, particularly during peak seasons when inventory turnover is higher.

Storage Fees (per pallet/bin)

Storage fees are incurred for keeping your products in the fulfillment center. These are typically calculated based on the amount of space your inventory occupies, measured in pallets or bins.

The structure of storage fees can include:

- Monthly Charges: A fixed fee per pallet/bin per month.

- Seasonal Adjustments: Higher rates during peak seasons (like holidays) when storage space is in high demand.

- Minimum Fees: Some providers may impose a minimum monthly storage fee regardless of your inventory levels.

To manage storage costs effectively, consider regular inventory audits and optimize your stock levels to avoid unnecessary fees.

Pick & Pack Fees (per item/order)

Pick and pack fees are charged for the labor involved in retrieving items from storage and preparing them for shipment. These fees can be structured per item or per order, depending on the fulfillment provider.

Key elements influencing pick and pack fees include:

- Order Complexity: Orders with multiple items may incur higher fees due to the additional time required to pick and pack.

- Special Requirements: Custom packaging or labeling may lead to additional charges.

- Volume Discounts: Higher order volumes might lead to reduced pick and pack fees per item.

Understanding these fees is crucial as they directly impact your order fulfillment costs. Efficient inventory management can help reduce the complexity and associated costs of picking and packing.

Shipping Fees

Shipping fees are a significant aspect of fulfillment pricing and are typically calculated based on the following factors:

- Weight and Dimensions: Heavier and larger packages incur higher shipping costs.

- Shipping Method: Different carriers and service levels (standard, express, etc.) have varying rates.

- Destination: Shipping to remote areas often costs more than shipping to urban locations.

- Volume Discounts: Many fulfillment providers negotiate rates with carriers based on shipping volume, which can be passed on to you.

To optimize shipping costs, consider negotiating rates with your fulfillment provider or exploring multiple carriers to find the best deals.

Tips for Getting an Accurate Quote

When seeking an accurate fulfillment pricing quote, keep these tips in mind:

- Provide Detailed Information: Share specifics about your product dimensions, weights, and expected order volumes to receive a tailored quote.

- Ask for a Breakdown: Request a detailed breakdown of all potential fees, including any hidden charges that may arise during the fulfillment process.

- Evaluate Different Providers: Compare quotes from multiple fulfillment centers to find the best balance of services and costs.

- Inquire About Discounts: Ask about volume discounts for shipping and storage, especially if you anticipate rapid growth in your order volume.

- Review Contracts Carefully: Ensure you understand the terms and conditions, particularly regarding minimum fees and seasonal adjustments.

By taking these steps, you can better navigate the complexities of fulfillment pricing and select a provider that aligns with your business needs.

Frequently Asked Questions (FAQs) about Fulfillment

1. ¿Qué es el fulfillment para ecommerce?

El fulfillment para ecommerce es el conjunto de procesos que permiten que un pedido realizado en una tienda online sea preparado y enviado al cliente. Esto incluye la gestión de inventario, almacenamiento, recepción de pedidos, embalaje, envío y manejo de devoluciones.

2. ¿Cuál es la diferencia entre un almacén y un centro de fulfillment?

Un almacén es un espacio donde se guardan productos, mientras que un centro de fulfillment es una instalación diseñada específicamente para manejar el proceso completo de recibir, almacenar, preparar y enviar pedidos. Los centros de fulfillment suelen contar con tecnología avanzada para optimizar la logística y mejorar la eficiencia.

3. ¿Qué es un 3PL?

Un 3PL, o proveedor de logística de terceros, es una empresa que gestiona todo el proceso logístico de otra empresa, incluyendo almacenamiento, gestión de inventario, preparación de pedidos y envío. Externalizar estos servicios permite a los negocios enfocarse en sus operaciones principales y escalar más rápidamente.

4. ¿Cuánto cuestan los servicios de fulfillment?

Los costos de los servicios de fulfillment pueden variar ampliamente según el proveedor y el volumen de pedidos. Generalmente, se cobran tarifas por almacenamiento, manejo de pedidos, envío y, en algunos casos, tarifas por devoluciones. Es recomendable solicitar cotizaciones a varios proveedores para comparar precios y servicios.

5. ¿Qué opciones de fulfillment existen para mi negocio?

Las principales opciones de fulfillment incluyen el fulfillment interno (gestionado por ti mismo), el dropshipping (donde el proveedor envía directamente al cliente) y la logística de terceros (3PL). La elección depende de factores como el volumen de pedidos, el tipo de productos y los recursos disponibles.

6. ¿Cuáles son las ventajas del dropshipping?

El dropshipping permite a los emprendedores evitar los costos de almacenamiento y manejo de inventario, ya que el proveedor se encarga de enviar los productos directamente a los clientes. Esto reduce el riesgo financiero y permite iniciar un negocio con una inversión inicial baja.

7. ¿Cómo puedo optimizar mi proceso de fulfillment?

Para optimizar tu proceso de fulfillment, considera implementar un software de gestión de inventario, automatizar el proceso de embalaje y envío, y evaluar constantemente el rendimiento de tus proveedores logísticos. También es importante establecer una buena comunicación con tu equipo y tus clientes para gestionar expectativas.

8. ¿Qué debo hacer si un cliente quiere devolver un producto?

Debes tener un proceso claro para gestionar devoluciones. Esto incluye proporcionar instrucciones sobre cómo devolver el producto, decidir si se ofrecerá un reembolso o un cambio, y asegurarte de que los artículos devueltos sean revisados y procesados de manera eficiente para volver a estar disponibles para la venta.

9. ¿Cómo afecta el fulfillment a la experiencia del cliente?

El fulfillment impacta directamente en la satisfacción del cliente. Un proceso de fulfillment eficiente asegura que los pedidos se envíen a tiempo y en buen estado, lo que genera confianza y fidelidad. Los retrasos o errores en el envío pueden resultar en insatisfacción y afectar la reputación de tu marca.

10. ¿Qué consideraciones debo tener en cuenta al elegir un proveedor de fulfillment?

Al elegir un proveedor de fulfillment, considera su experiencia en la industria, la tecnología que utilizan, la flexibilidad de sus servicios, los costos asociados y la calidad de su atención al cliente. También es crucial revisar las reseñas y testimonios de otros clientes para asegurarte de que el proveedor cumpla con tus expectativas.

Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

Evaluando la Externalización del Fulfillment

La externalización del fulfillment puede ser una decisión transformadora para tu negocio de comercio electrónico. Entre los beneficios más destacados se encuentran el ahorro de tiempo, la escalabilidad y la experiencia especializada que un proveedor de fulfillment puede ofrecer. Al delegar el manejo de inventarios, el empaquetado y el envío a un socio experto, puedes liberar recursos valiosos que puedes reinvertir en áreas críticas de tu negocio, como marketing y desarrollo de productos. Esto no solo mejora la eficiencia operativa, sino que también permite a tu equipo centrarse en el crecimiento y la satisfacción del cliente.

La escalabilidad es otro aspecto crucial. A medida que tu negocio crece, la demanda de pedidos puede variar drásticamente. Un proveedor de fulfillment puede adaptarse rápidamente a estos cambios, gestionando volúmenes crecientes sin la necesidad de inversiones significativas en infraestructura o personal adicional. Esto es especialmente valioso en temporadas altas o durante lanzamientos de productos, donde la capacidad de respuesta puede marcar la diferencia entre el éxito y el fracaso.

Sin embargo, es fundamental seleccionar el socio adecuado. Un mal proveedor puede afectar negativamente la percepción de tu marca y la experiencia del cliente. Por lo tanto, realiza una investigación exhaustiva y considera factores como la reputación, la experiencia en tu sector y la capacidad de ofrecer un servicio al cliente excepcional.

Acción Estratégica

Antes de tomar una decisión, te recomendamos auditar tu proceso actual de envío y fulfillment. Evalúa si estás aprovechando al máximo tus recursos y si estás preparado para el crecimiento. Considera si una asociación con un proveedor de fulfillment podría ser el próximo paso estratégico para llevar tu negocio al siguiente nivel. La correcta elección podría no solo optimizar tus operaciones, sino también impulsar tu crecimiento y rentabilidad a largo plazo.

Important Disclaimer

⚠️ Important Disclaimer

The information in this guide is for educational purposes. Fulfillment services, pricing, and platform features change frequently. Always conduct your own due diligence and consult with providers directly before making business decisions.