How Order Fulfillment Works: A Step-by-Step Guide for Businesses

What is E-commerce Fulfillment? An Introduction for Growing Businesses

Understanding E-commerce Fulfillment: A Key to Success for Growing Businesses

As your e-commerce business starts to grow, the excitement of increased sales can quickly turn into a daunting challenge—packing and shipping orders. The logistics of getting products into the hands of customers can feel overwhelming, especially as order volumes rise. This is where e-commerce fulfillment comes into play, streamlining your operations and allowing you to focus on what you do best: growing your business.

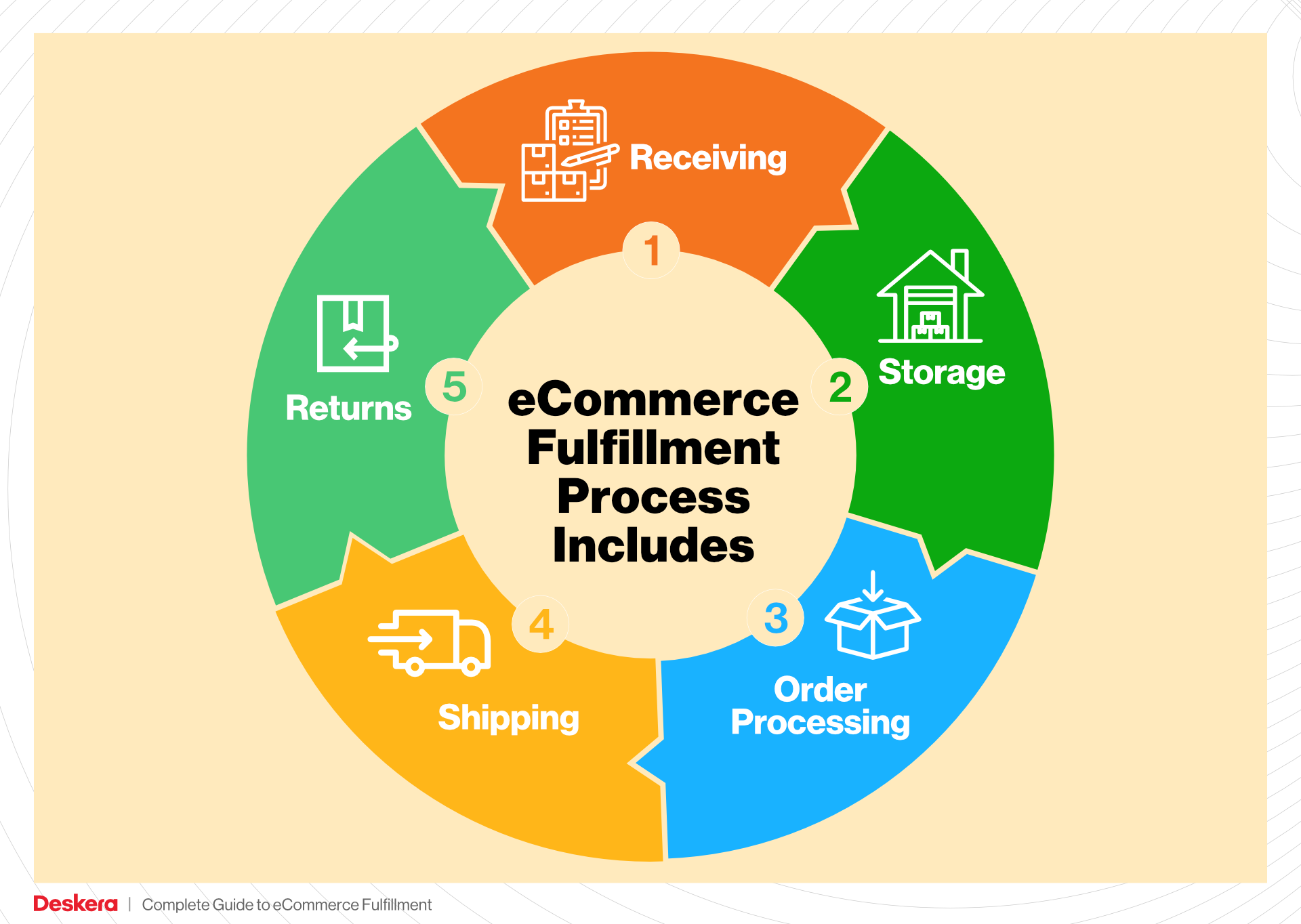

At its core, fulfillment is the process of getting a product from your inventory to your customer’s doorstep. It encompasses everything from receiving and storing inventory to packing orders, managing shipping logistics, and handling returns. For many businesses, mastering this process can be the difference between success and stagnation.

This guide aims to demystify the world of e-commerce fulfillment for growing businesses. We will explore various fulfillment models, including Third-Party Logistics (3PL) and Fulfillment by Amazon (FBA), so you can identify which approach aligns best with your business needs. Each model offers unique advantages and challenges, and understanding them is crucial to making informed decisions.

In addition to fulfillment models, we will delve into the core services typically offered by fulfillment partners. These services can include inventory management, order processing, shipping solutions, and customer service support. Knowing what to expect from potential partners can help you assess their capabilities and ensure they meet your operational requirements.

Choosing the right fulfillment partner is critical for your success. We will provide insights into what factors to consider—such as location, technology integration, scalability, and customer service. A well-chosen partner can enhance your operational efficiency and improve customer satisfaction.

Finally, we will discuss pricing structures in the fulfillment industry. Understanding the costs associated with different fulfillment options will empower you to budget effectively and avoid unexpected expenses.

The goal of this guide is to equip you with the knowledge and tools necessary to make smart, strategic decisions about your logistics. By optimizing your fulfillment process, you can enhance your customer experience, reduce operational headaches, and ultimately drive your business growth. Let’s navigate this essential aspect of e-commerce together, ensuring you are well-prepared for the challenges and opportunities that lie ahead.

What You’ll Learn In This Guide

- What is E-commerce Fulfillment? An Introduction for Growing Businesses

- The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

- Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

- A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

- Core Services Offered by Fulfillment Centers

- How to Choose a Fulfillment Partner: A 6-Point Checklist

- Understanding Fulfillment Pricing: A Breakdown of Common Fees

- Frequently Asked Questions (FAQs) about Fulfillment

- Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

- Important Disclaimer

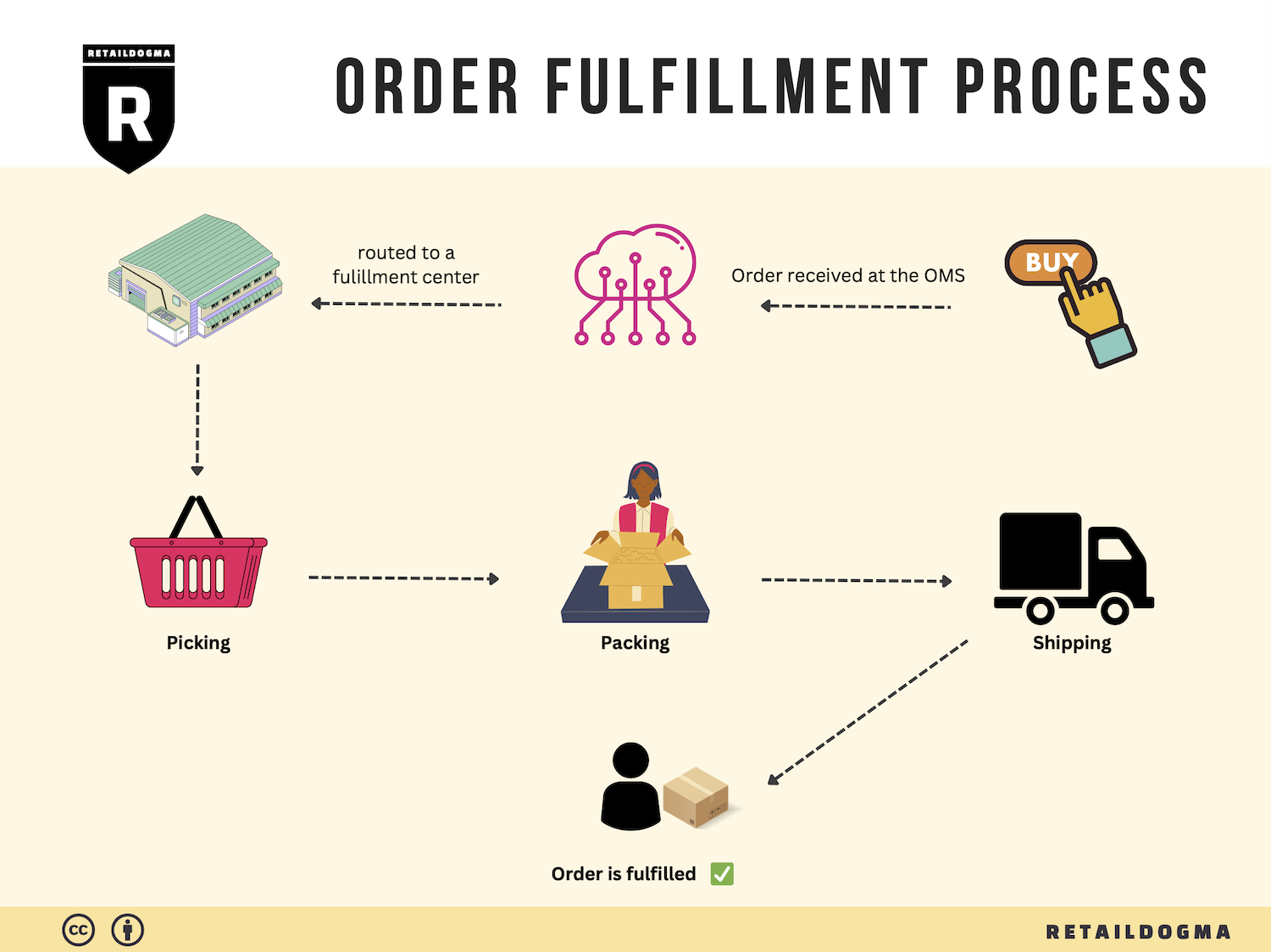

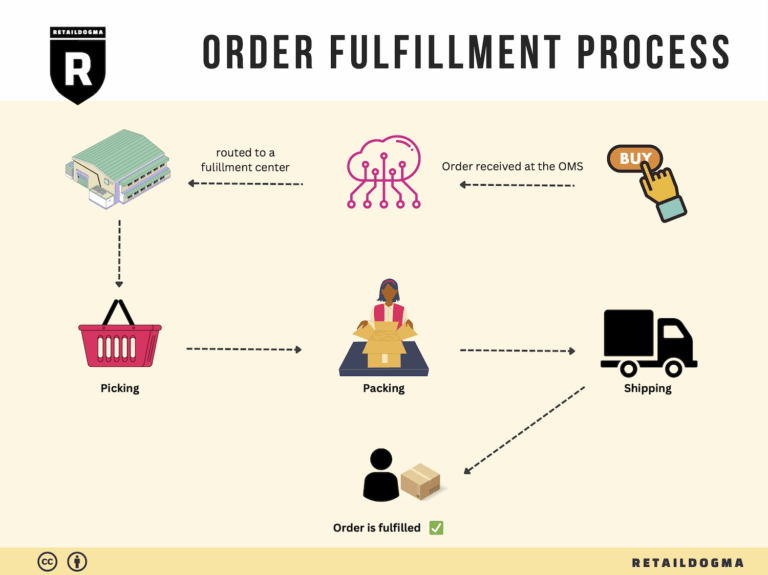

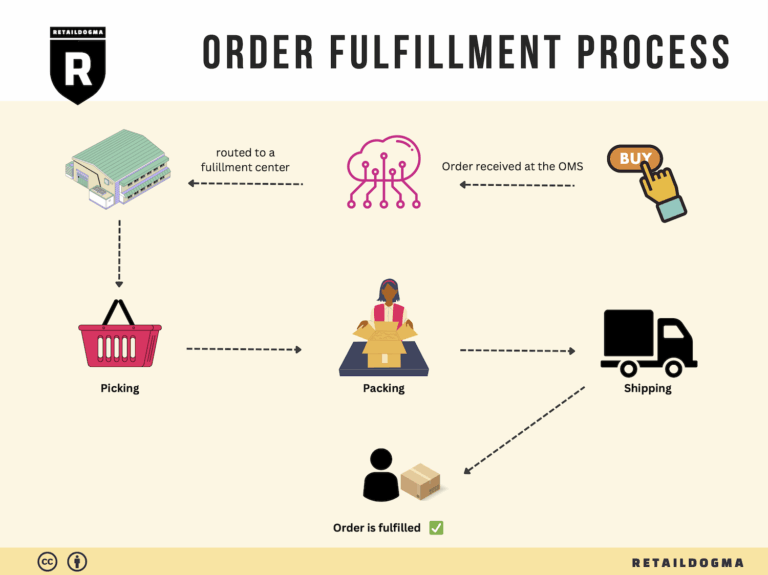

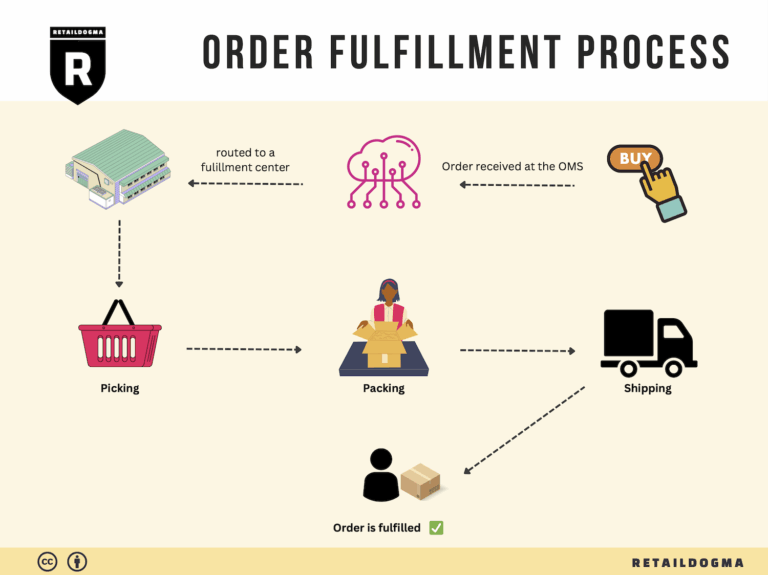

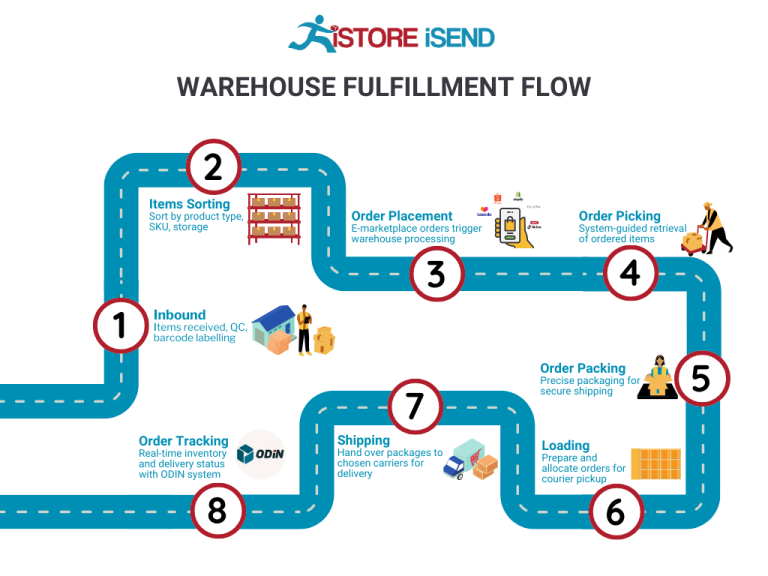

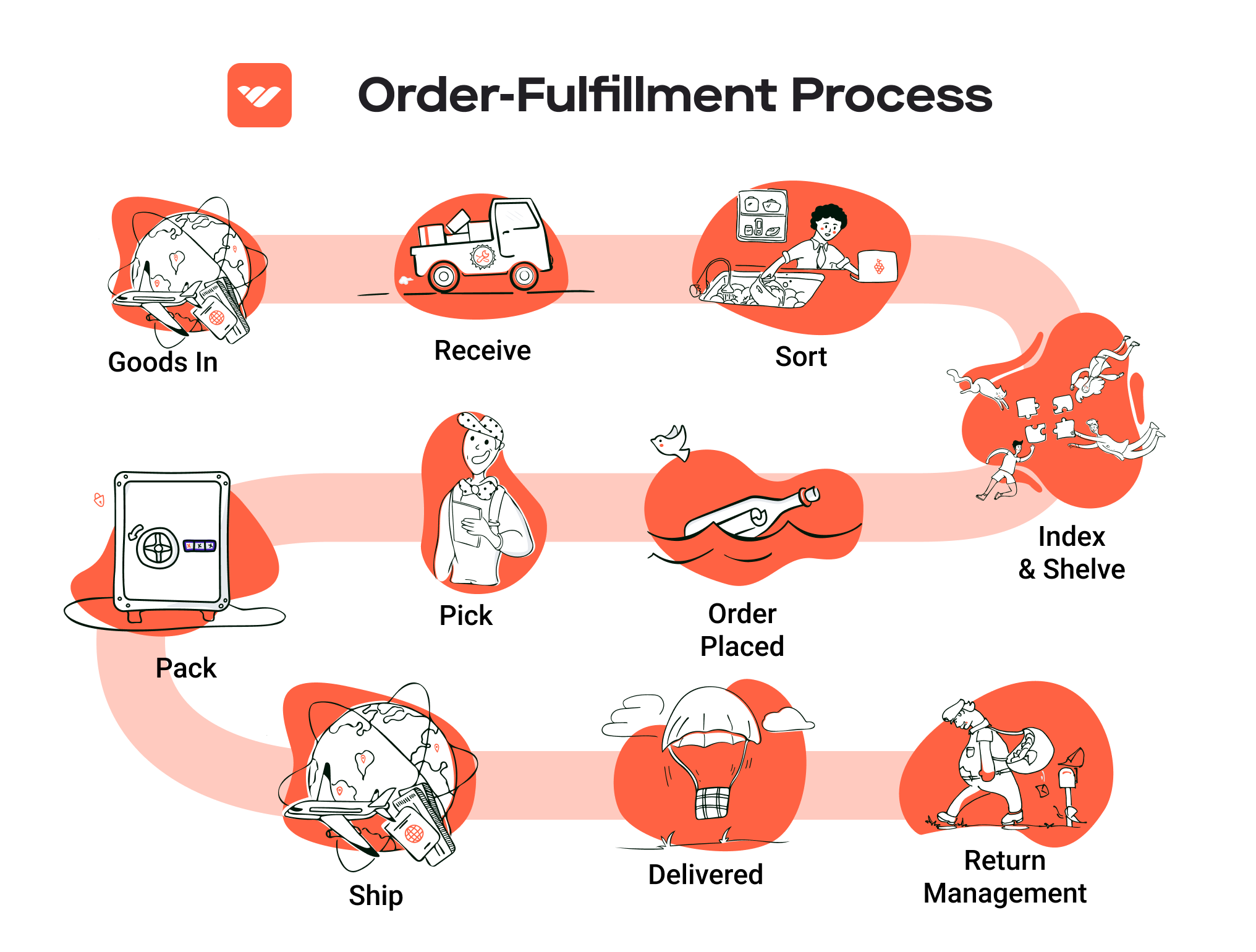

The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

1. Receiving Inventory

The order fulfillment process begins with receiving inventory at the fulfillment center, such as Sam’s Club’s facility in Groveport, OH. During this step, products arrive from suppliers and manufacturers, where they are checked for accuracy against purchase orders. This includes verifying quantities, inspecting for damage, and ensuring that the right items have been delivered.

Importance: This step is crucial as it sets the foundation for the entire fulfillment operation. If errors occur at this stage, they can lead to inventory discrepancies, affecting stock levels and customer satisfaction. Efficient receiving practices help maintain accurate inventory counts, which is vital for effective inventory management.

Key Term: SKU (Stock Keeping Unit) – A unique identifier assigned to each product, facilitating tracking and inventory management.

2. Warehouse Storage

Once inventory is received and verified, it is organized and stored within the warehouse. The layout of the storage area is designed for efficiency, with products grouped by category or frequency of sale to streamline the picking process later.

Importance: Effective warehouse storage minimizes the time taken to locate products when orders are placed. Proper organization helps optimize space utilization and can reduce operational costs. For instance, high-demand items may be stored closer to packing stations to facilitate quicker access.

Key Term: Bin Location – A specific storage area designated for a product, helping workers quickly locate items during the picking process.

3. Order Picking

When a customer places an order, the fulfillment center initiates the order picking process. Workers use tools such as pick lists or technology-driven systems to locate and retrieve the items needed for the order. Depending on the fulfillment strategy, picking can be done manually or via automated systems.

Importance: Order picking is a critical step as it directly impacts order accuracy and speed. Errors during picking can lead to incorrect shipments, resulting in customer dissatisfaction and increased return rates. Efficient picking strategies enhance productivity and ensure that orders are fulfilled correctly.

Key Term: Pick List – A document or digital tool that outlines the items and quantities to be picked for a specific order, guiding fulfillment associates through the warehouse.

4. Order Packing

After items are picked, they proceed to the packing station. Here, associates pack the products into boxes, ensuring that they are secure and protected during transit. This step also involves labeling packages for shipping and including any necessary documentation, such as invoices or return instructions.

Importance: Proper packing is vital for preventing damage during shipping and ensuring that the order arrives in perfect condition. Additionally, clear labeling and documentation enhance the customer experience and streamline the returns process if needed. Well-packed orders can also lead to reduced shipping costs and fewer claims for damaged goods.

Key Term: Packing Slip – A document included in the shipment that details the contents of the package, serving as a receipt for the customer.

5. Shipping & Delivery

The final step in the order fulfillment process is shipping and delivery. Once the order is packed, it is handed over to a carrier for transportation to the customer’s address. This may involve various shipping options, including standard, expedited, or same-day delivery, depending on customer preferences and service agreements.

Importance: Shipping and delivery are often the last touchpoint a customer has with the brand, making it a critical factor in their overall satisfaction. Timely and accurate delivery can enhance customer loyalty and encourage repeat business. Efficient shipping practices also help businesses manage costs and improve operational efficiency.

Key Term: Last-Mile Delivery – The final leg of the shipping journey, where the package is delivered from a transportation hub to the final destination (the customer’s door), often representing the most challenging and expensive part of the logistics process.

By understanding and optimizing each of these steps in the order fulfillment process, e-commerce businesses can enhance efficiency, reduce costs, and improve customer satisfaction, ultimately driving growth and scalability.

Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

Fulfillment Model Comparison

| Model | Who Handles Inventory | Best For (Business Stage) | Key Advantage | Key Disadvantage |

|---|---|---|---|---|

| In-House Fulfillment | Business (self-managed) | Established businesses | Full control over operations and inventory | High overhead costs and resource commitment |

| Third-Party Logistics (3PL) | 3PL Provider | Growing and scaling businesses | Scalable solutions with expertise and efficiency | Less control over fulfillment processes |

| Dropshipping | Supplier | Startups and niche businesses | Low upfront investment and minimal risk | Lower profit margins and dependency on suppliers |

In-House Fulfillment

In-house fulfillment involves managing the entire logistics process within the company. This model is most suitable for established businesses with stable demand and sufficient resources to invest in warehousing, staffing, and technology. By handling inventory directly, businesses retain complete control over their operations, which allows for customization in processes and quality assurance. However, this model often comes with high overhead costs, including facility management, labor, and technology investments. As a result, businesses may find it challenging to scale quickly due to the resource-intensive nature of in-house operations. Additionally, if demand fluctuates, they risk overstocking or understocking inventory, which can lead to increased costs or missed sales opportunities.

Third-Party Logistics (3PL)

Third-party logistics (3PL) providers offer a flexible solution for businesses looking to scale their fulfillment operations without the burden of managing logistics themselves. This model is ideal for growing companies that want to enhance their distribution capabilities without significant upfront investments in infrastructure. 3PL companies like Radial, based in Groveport, Ohio, bring expertise and advanced technology to streamline fulfillment processes, including inventory management, order processing, and shipping. The key advantage of using a 3PL is scalability; businesses can easily adjust their logistics services according to demand fluctuations, seasonal peaks, or expansion into new markets. However, this model does come with a trade-off: businesses have less control over the fulfillment process, which can lead to inconsistencies in service quality or delays if the 3PL provider does not meet performance expectations.

Dropshipping

Dropshipping is a fulfillment model that allows businesses to sell products without holding any inventory. Instead, when a customer places an order, the retailer purchases the item from a third-party supplier who then ships it directly to the customer. This model is particularly advantageous for startups and niche businesses with limited capital, as it requires minimal upfront investment. Since there is no need to manage inventory, businesses can focus on marketing and customer service rather than logistics. However, dropshipping often comes with lower profit margins, as suppliers typically charge higher prices for their services. Furthermore, businesses are heavily reliant on their suppliers for product quality, shipping times, and stock availability, which can lead to customer dissatisfaction if the supplier fails to deliver. Overall, while dropshipping can provide a low-risk entry point into e-commerce, it also requires careful supplier selection and effective communication to ensure a positive customer experience.

In conclusion, selecting the right fulfillment model depends on your business stage, resource availability, and long-term goals. Understanding the nuances of each model will empower e-commerce business owners and operations managers to make informed decisions that align with their growth strategies.

A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

Understanding Fulfillment by Amazon (FBA)

Fulfillment by Amazon (FBA) is a service provided by Amazon that allows sellers to store their products in Amazon’s fulfillment centers. Amazon then takes care of storage, packaging, and shipping of these products directly to customers. This service is particularly attractive to e-commerce business owners seeking to streamline their logistics and provide a seamless shopping experience for their customers.

When a customer orders a product, Amazon handles the entire fulfillment process. This includes picking the product from the warehouse, packing it, and shipping it out. Sellers can also benefit from Amazon’s customer service and return handling, which can significantly reduce the operational burden on their businesses.

How FBA Works

-

Product Preparation: Sellers prepare their products according to Amazon’s guidelines, which include labeling, packaging, and ensuring compliance with safety regulations.

-

Shipping to Amazon: Once products are ready, sellers ship them to Amazon’s fulfillment centers. Amazon has numerous centers across the globe, allowing for efficient distribution.

-

Storage: Products are stored in Amazon’s warehouses until sold. Sellers are charged storage fees based on the amount of space their products occupy.

-

Order Fulfillment: When an order is placed, Amazon picks, packs, and ships the product. Customers typically receive their orders quickly, often within two days if they are Prime members.

-

Customer Service: Amazon provides customer service for FBA orders, handling inquiries and returns on behalf of the seller.

Pros of Using FBA

1. Prime Eligibility

Products fulfilled by Amazon are eligible for Amazon Prime, which is a significant advantage. Prime members enjoy free two-day shipping, making your products more attractive to a vast customer base. This can lead to increased sales, as many consumers prefer to shop for Prime-eligible items.

2. Customer Trust

Amazon has built a strong reputation for reliability and customer service. When sellers use FBA, they benefit from this trust, as customers often feel more confident purchasing items that are fulfilled by Amazon. The “Fulfilled by Amazon” badge can increase conversion rates and enhance brand credibility.

3. Multi-Channel Fulfillment

FBA isn’t limited to Amazon.com sales. Sellers can utilize FBA for multi-channel fulfillment, allowing them to sell on other platforms (like eBay or their own websites) while still using Amazon’s logistics network. This flexibility can be a game changer for businesses looking to expand their reach without overhauling their logistics.

4. Scalable Operations

FBA allows sellers to scale their operations without the need to invest heavily in warehousing, staffing, and shipping logistics. As sales increase, sellers can rely on Amazon’s infrastructure to manage higher volumes of orders seamlessly.

5. Streamlined Returns Management

Handling returns can be a headache for e-commerce businesses. With FBA, Amazon manages returns for sellers, making the process straightforward for both the seller and the customer. This can enhance customer satisfaction and loyalty.

Cons of Using FBA

1. High Fees

One of the most significant drawbacks of FBA is the cost. Amazon charges various fees, including storage fees for the space your products occupy and fulfillment fees for each item sold. For some sellers, especially those with lower margins, these fees can significantly eat into profits.

2. Strict Inventory Rules

Amazon has specific guidelines regarding inventory management, including limitations on how many units can be sent to fulfillment centers. Sellers must also manage their inventory levels carefully to avoid long-term storage fees, which can apply to products that remain in the warehouse for extended periods.

3. Commingling Risks

When using FBA, products from different sellers can be stored together in the same warehouse, known as commingling. This can pose risks, such as receiving returns that do not belong to your inventory. If a customer returns a defective product, it could potentially be sent back to your stock, impacting your seller rating and customer satisfaction.

4. Loss of Control

By using FBA, sellers relinquish some control over their fulfillment process. This includes how products are handled, packaged, and delivered. For businesses that prioritize brand experience, this can be a significant concern.

5. Complexity in Returns

While Amazon manages returns, this can sometimes lead to complications. For example, if a product is returned and not properly documented, it could affect your inventory counts or lead to lost sales if the product cannot be resold.

Who is FBA Best For?

FBA is ideal for a variety of sellers, particularly those who:

-

Have High Sales Volume: Sellers with a high volume of sales can benefit from the efficiency and speed of Amazon’s fulfillment network, offsetting the costs associated with FBA.

-

Sell Consumer Products: Products that have high turnover and are in demand are excellent candidates for FBA. Items that are frequently bought by consumers, such as electronics, household goods, or fashion, tend to perform well.

-

Desire Prime Eligibility: Sellers looking to tap into the Prime customer base will find FBA essential for gaining visibility and increasing sales.

-

Want to Scale Quickly: Businesses that are experiencing rapid growth or those that plan to expand into new markets can leverage FBA’s infrastructure to scale without the need for significant upfront investment in logistics.

-

Prefer a Hands-Off Approach: For entrepreneurs who want to focus on marketing and product development rather than logistics, FBA provides a solution that allows for greater operational efficiency.

In summary, while FBA offers numerous benefits, including Prime eligibility and customer trust, it is crucial for sellers to weigh these advantages against the potential downsides, such as fees and inventory management challenges. By understanding both the pros and cons, e-commerce business owners can make informed decisions about whether FBA aligns with their growth strategies.

Core Services Offered by Fulfillment Centers

Inventory Management & Warehousing

Inventory management and warehousing are foundational services provided by fulfillment centers, ensuring that e-commerce businesses maintain optimal stock levels while minimizing storage costs. This service involves the systematic tracking and management of inventory throughout its lifecycle—from the moment products arrive at the fulfillment center until they are shipped to customers.

What It Is: Fulfillment centers utilize advanced inventory management systems (IMS) to monitor stock levels in real-time, track incoming and outgoing products, and forecast future inventory needs based on sales trends. They often employ barcode scanning and RFID technology to enhance accuracy and efficiency.

Benefits: For e-commerce businesses, effective inventory management translates into reduced carrying costs and improved cash flow. By having precise visibility into inventory levels, businesses can avoid stockouts, which can lead to lost sales, and overstock situations, which can tie up capital. Additionally, fulfillment centers often offer climate-controlled warehousing options, ensuring that products are stored under optimal conditions, thereby maintaining their quality and extending their shelf life.

Pick and Pack Services

Pick and pack services are critical for fulfilling customer orders accurately and efficiently. This process involves selecting items from the warehouse based on incoming orders and then packing them for shipment.

What It Is: When an order is received, fulfillment center staff use picking technology to locate items in the warehouse. Once the items are picked, they are packed into boxes or containers, often using materials that protect the products during transit. Many fulfillment centers also offer customizable packing options, such as branded packaging, to enhance the unboxing experience for customers.

Benefits: Efficient pick and pack services ensure that orders are processed quickly, which is essential for meeting customer expectations in today’s fast-paced e-commerce environment. This service minimizes the chances of errors, such as sending the wrong item or quantity, which can negatively impact customer satisfaction and lead to costly returns. Furthermore, by outsourcing these processes, businesses can focus on core activities such as marketing and product development, allowing for greater scalability as order volumes increase.

Kitting and Assembly

Kitting and assembly services add value to products by bundling multiple items into a single package or preparing products for sale. This service is particularly beneficial for businesses that offer complex products or promotional bundles.

What It Is: Kitting involves assembling various items into a ready-to-sell package. For example, a fulfillment center might bundle a set of kitchen utensils into a single kit for a promotional campaign. Assembly services may also include putting together components of a product that require pre-assembly before being shipped to the customer.

Benefits: For e-commerce businesses, kitting and assembly services streamline the fulfillment process, reduce handling time, and enhance product presentation. By offering kits or bundled products, businesses can increase average order value and attract customers looking for convenience. This service also allows businesses to respond quickly to market demands, enabling them to launch promotions or seasonal offerings with minimal lead time. Ultimately, kitting and assembly can lead to improved customer satisfaction as customers receive products that are ready for immediate use.

Returns Management (Reverse Logistics)

Returns management, or reverse logistics, is a crucial service that addresses the challenges of product returns and exchanges in e-commerce. As online shopping continues to grow, so does the volume of returns, making efficient returns management vital for maintaining customer satisfaction and loyalty.

What It Is: Returns management involves processing returned items, inspecting them for damage, restocking them, and determining their next steps—whether they will be resold, repaired, or recycled. Fulfillment centers often have dedicated teams and systems in place to handle returns efficiently.

Benefits: A well-managed returns process can significantly enhance the customer experience. By providing hassle-free returns, e-commerce businesses can build trust and encourage repeat purchases. Additionally, effective returns management helps minimize losses associated with returned merchandise. By quickly restocking items that are still sellable, businesses can recover revenue and maintain inventory accuracy. Furthermore, insights gained from analyzing return data can inform product development and inventory decisions, ultimately leading to improved product offerings and reduced return rates.

In summary, leveraging the core services offered by fulfillment centers allows e-commerce businesses to scale efficiently while focusing on their core competencies. From inventory management to returns processing, these services play a critical role in enhancing operational efficiency, customer satisfaction, and overall business growth.

How to Choose a Fulfillment Partner: A 6-Point Checklist

Location & Warehouse Network

Importance:

The geographic location of your fulfillment partner can significantly impact shipping times and costs. A partner with warehouses strategically located near your target customers can ensure faster delivery and lower shipping expenses.

Questions to Ask:

– What is the location of your warehouses, and how do they align with my customer base?

– How do you manage inventory across multiple locations?

– Can you provide information on your shipping capabilities to major regions?

Technology & Integrations

Importance:

In today’s digital landscape, the technology used by your fulfillment partner can streamline operations, enhance accuracy, and provide real-time visibility into inventory and order status. A partner that offers robust technology and seamless integration with your e-commerce platform is essential for efficient operations.

Questions to Ask:

– What fulfillment management system do you use, and how does it integrate with my e-commerce platform?

– Do you offer real-time tracking and reporting capabilities for orders and inventory?

– How do you handle updates and improvements to your technology?

Specializations (e.g., Cold Storage, Oversized Items)

Importance:

Different businesses have unique needs based on the nature of their products. If you deal in perishables, fragile items, or oversized products, it’s crucial to choose a partner that specializes in those areas to ensure proper handling and storage.

Questions to Ask:

– What specific types of products do you specialize in handling (e.g., cold storage, fragile items)?

– What are your protocols for managing specialized inventory?

– Can you accommodate future needs for different product types?

Scalability & Capacity

Importance:

As your business grows, your fulfillment needs will change. A partner that can scale with your business—whether through increased storage capacity or additional services—is vital for sustained growth.

Questions to Ask:

– What is your current capacity, and how do you manage fluctuations in order volume?

– Can you accommodate seasonal spikes in demand, and if so, how?

– What are your plans for expansion or enhancement of your facilities and services?

Pricing and Contracts

Importance:

Understanding the pricing structure and contract terms is critical to ensure that the partnership aligns with your financial goals. Clarity in pricing helps avoid unexpected costs and ensures budget adherence.

Questions to Ask:

– What is your pricing model (e.g., per order, per item, monthly fees)?

– Are there any additional fees I should be aware of (e.g., storage fees, handling fees)?

– What are the terms of the contract, including cancellation policies and renewal processes?

Customer Support & Reviews

Importance:

Exceptional customer support is essential in maintaining a successful partnership. Your fulfillment partner should be responsive and proactive in addressing any issues that arise. Additionally, researching reviews can provide insight into the partner’s reliability and service quality.

Questions to Ask:

– What customer support options do you offer (e.g., dedicated account manager, 24/7 support)?

– How do you handle issues or errors in order fulfillment?

– Can you provide references or case studies from similar businesses?

Conclusion

Choosing the right fulfillment partner is a critical decision that can significantly impact your e-commerce operations. By carefully considering these six points—location and warehouse network, technology and integrations, specializations, scalability and capacity, pricing and contracts, and customer support and reviews—you can make an informed decision that supports your business’s growth and success.

Take the time to evaluate potential partners against this checklist and ask the right questions to ensure they align with your operational needs and customer expectations. A well-chosen fulfillment partner will not only enhance your logistics but also contribute to your overall customer satisfaction and business growth.

Understanding Fulfillment Pricing: A Breakdown of Common Fees

Initial Setup Fees

Initial setup fees are typically charged when a business first engages with a fulfillment center. These fees cover the costs associated with onboarding your business into the fulfillment system. Charges may include the configuration of your products in their inventory management system, establishing shipping preferences, and setting up packaging requirements.

The calculation of initial setup fees can vary widely based on the complexity of your operations. Basic setups may cost a few hundred dollars, while more complex integrations, particularly those requiring custom software development or extensive training, can run into the thousands. To mitigate these costs, ensure you have all necessary product data and logistics information prepared before engaging with the fulfillment center.

Receiving Fees

Receiving fees are incurred when the fulfillment center accepts and processes your incoming inventory. This includes unloading shipments, inspecting for damages, and entering items into their inventory system.

Typically, receiving fees are calculated on a per shipment basis, with costs per pallet or box. For example, a fulfillment center may charge $25 per pallet or $5 per box received. The total fee will depend on the volume of shipments and the efficiency of the receiving process. To minimize these costs, consider consolidating shipments to reduce the frequency of deliveries.

Storage Fees (per pallet/bin)

Storage fees are charged for the space your inventory occupies within the fulfillment center. This fee is crucial for managing inventory turnover and ensuring that products are readily available for shipping.

Storage fees are generally calculated on a monthly basis, either per pallet or per bin. For instance, you might see rates like $15 per pallet per month or $5 per bin. The exact fee structure can depend on the type of products you store (e.g., perishables may incur higher fees) and the location of the fulfillment center. To optimize your storage costs, regularly audit your inventory to identify slow-moving items that may need to be discounted or removed.

Pick & Pack Fees (per item/order)

Pick and pack fees are charged for the labor involved in selecting items from storage and preparing them for shipment. This includes picking the correct products, packing them securely, and labeling for delivery.

These fees can be structured in two ways: per item or per order. For example, a fulfillment center might charge $0.50 per item picked and packed, or a flat fee of $2.00 per order, regardless of the number of items. Understanding your order volume and item variety can help you negotiate more favorable terms. To keep these fees in check, consider optimizing your product offerings and minimizing SKUs to streamline the picking process.

Shipping Fees

Shipping fees are a significant component of fulfillment pricing, as they cover the costs of transporting your products from the fulfillment center to your customers. Shipping fees can vary based on several factors, including the weight and dimensions of the package, the shipping method (standard, expedited, etc.), and the destination.

Shipping fees are generally calculated based on carrier rates, which can fluctuate due to fuel prices, distance, and service level. Many fulfillment centers offer discounted shipping rates through partnerships with carriers, which can significantly lower your costs. To manage shipping fees effectively, consider integrating shipping software that can compare rates from multiple carriers, allowing you to choose the most cost-effective option for each order.

Tips for Getting an Accurate Quote

-

Provide Detailed Information: When requesting a quote, provide comprehensive information about your products, order volumes, and shipping destinations. The more details you share, the more accurate the quote will be.

-

Ask About Additional Fees: Clarify all potential fees beyond the basic pricing structure. This includes setup fees, seasonal surcharges, and any costs associated with special handling or packaging.

-

Negotiate Terms: Don’t hesitate to negotiate fees, especially if you have a high volume of orders or plan to grow significantly. Many fulfillment centers are willing to adjust pricing for long-term partnerships.

-

Consider Scalability: Ensure that the fulfillment center can accommodate your growth. Ask about pricing changes as your business scales to avoid surprises down the road.

-

Request a Trial Period: If possible, negotiate a trial period to evaluate the fulfillment center’s efficiency and service quality. This can help you determine if the pricing structure aligns with your business needs before making a long-term commitment.

By understanding these common fulfillment pricing models and implementing these strategies, you can effectively manage your fulfillment costs while scaling your e-commerce business.

Frequently Asked Questions (FAQs) about Fulfillment

1. What is the Sam’s Club Fulfillment Center 9475, and what services does it provide?

The Sam’s Club Fulfillment Center 9475, located in Groveport, OH, is a state-of-the-art facility designed to handle the logistics of eCommerce orders. It specializes in efficiently receiving, storing, and shipping a wide range of products to meet the demands of online shoppers. The center focuses on quick turnaround times, ensuring that the most popular items are delivered to customers in two days or less.

2. How does the fulfillment process work at Sam’s Club Fulfillment Center 9475?

The fulfillment process at Sam’s Club 9475 begins with receiving incoming shipments, followed by organizing and storing products in an optimized layout. When an order is placed, the center employs advanced technologies to pick, pack, and ship items to customers. The goal is to ensure that each order is accurate, delivered on time, and in perfect condition.

3. What technologies are used at Sam’s Club Fulfillment Center 9475?

The facility utilizes cutting-edge technology, including automated picking systems, inventory management software, and real-time tracking systems. These technologies help streamline operations, reduce errors, and enhance overall efficiency, ensuring that orders are processed quickly and accurately.

4. What is the difference between a warehouse and a fulfillment center?

A warehouse primarily serves as a storage space for goods, focusing on inventory management. In contrast, a fulfillment center is designed for the complete order fulfillment process, including picking, packing, and shipping products directly to customers. Fulfillment centers are equipped to handle eCommerce needs, emphasizing speed and accuracy in order processing.

5. What is a 3PL, and how does it relate to Sam’s Club Fulfillment Center 9475?

A 3PL, or third-party logistics provider, offers logistics services, including warehousing, fulfillment, and transportation management, to businesses. While Sam’s Club Fulfillment Center 9475 operates as an internal fulfillment facility for Sam’s Club, many eCommerce companies partner with 3PLs to manage their supply chain needs, particularly when scaling their operations.

6. How much do fulfillment services cost?

The cost of fulfillment services can vary widely based on factors such as order volume, storage space needed, and the complexity of the fulfillment process. On average, businesses can expect to pay for storage fees, picking and packing fees, and shipping costs. It’s essential to compare providers and tailor solutions to meet specific business needs for optimal cost efficiency.

7. What types of products are handled at Sam’s Club Fulfillment Center 9475?

The facility manages a diverse range of products, focusing on the top 2,000 most-purchased items on the Sam’s Club website. This includes groceries, electronics, household goods, and more. The goal is to ensure that popular items are readily available for quick delivery to customers.

8. What are the employment opportunities at Sam’s Club Fulfillment Center 9475?

The fulfillment center has created numerous job opportunities, including positions in warehousing, order fulfillment, and management. Positions often include freight handlers, inventory specialists, and logistical coordinators, among others. Interested candidates can find job openings on the Walmart careers website.

9. How does Sam’s Club ensure order accuracy and quality at the fulfillment center?

Sam’s Club employs rigorous quality control measures throughout the fulfillment process. This includes inspecting incoming shipments for damage, utilizing advanced picking technologies to minimize errors, and conducting regular audits of inventory. The aim is to maintain high standards of accuracy and customer satisfaction.

10. What should I consider when choosing a fulfillment partner for my eCommerce business?

When selecting a fulfillment partner, consider factors such as their location, technology capabilities, scalability, and customer service. It’s also important to evaluate their experience with your product types, their ability to meet your delivery timelines, and their pricing structure. A strong fulfillment partner can significantly impact your business’s efficiency and customer satisfaction.

Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

Evaluating the Benefits of Outsourcing Fulfillment

Outsourcing fulfillment can be a game changer for e-commerce businesses seeking to scale efficiently. The primary advantages include significant time savings, enhanced scalability, and access to specialized expertise. By leveraging a third-party fulfillment service, you can redirect your focus from logistical challenges to core business functions, such as marketing and customer engagement. This shift allows for a more strategic approach to growth, ultimately driving sales and improving customer satisfaction.

Scalability is another critical factor. As your business grows, so do the complexities of your logistics operations. A robust fulfillment partner can seamlessly adjust to your changing needs, whether that means managing seasonal spikes in demand or expanding into new markets. This flexibility is vital in today’s fast-paced e-commerce landscape, where consumer expectations for quick delivery and reliable service continue to rise.

Moreover, partnering with an experienced fulfillment provider grants you access to industry best practices and state-of-the-art technology. This expertise ensures that your operations run smoothly, from inventory management to shipping, reducing errors and enhancing overall efficiency.

However, the choice of a fulfillment partner is paramount. Not all providers offer the same level of service, so it’s essential to conduct thorough research and select a partner that aligns with your business goals and values.

To determine if outsourcing fulfillment is the right next step for your business, consider conducting an audit of your current shipping and logistics processes. Assess areas where you face challenges or bottlenecks, and evaluate how a fulfillment service could streamline operations. This strategic analysis will provide clarity on whether partnering with a fulfillment center, such as Sam’s Club’s Groveport facility, is the key to unlocking your business’s growth potential.

Important Disclaimer

⚠️ Important Disclaimer

The information in this guide is for educational purposes. Fulfillment services, pricing, and platform features change frequently. Always conduct your own due diligence and consult with providers directly before making business decisions.