Ecommerce Fulfillment Services: The Ultimate Guide (2025)

What is E-commerce Fulfillment? An Introduction for Growing Businesses

Understanding E-commerce Fulfillment: A Key to Growth

As an e-commerce business owner, you may find yourself grappling with the overwhelming tasks of packing and shipping orders, especially as your sales grow. This common pain point can divert your focus from essential activities like marketing, product development, and customer engagement. Understanding e-commerce fulfillment is crucial to streamline your operations and ensure that your customers receive their products promptly and efficiently.

E-commerce fulfillment is simply the process of getting a product from your inventory into the hands of your customers. It encompasses everything from receiving and storing inventory to picking, packing, and shipping orders. In today’s competitive online marketplace, the right fulfillment strategy can significantly impact your business’s success and customer satisfaction.

This guide will delve into various fulfillment models that can suit your growing business needs. We will explore Third-Party Logistics (3PL) and Fulfillment by Amazon (FBA), among others, providing insights into how these models function and their respective benefits. Understanding these options will help you identify the best fit for your operations.

Additionally, we will cover the core services that fulfillment partners typically offer, including inventory management, order processing, and shipping logistics. By knowing what services are available, you can better assess what your business requires and how to optimize your fulfillment processes.

Choosing the right fulfillment partner is vital to your operational success. We’ll discuss key factors to consider when selecting a partner, such as their technology capabilities, geographic reach, and customer service. Making an informed choice can help you avoid common pitfalls and enhance your overall efficiency.

Finally, pricing is a critical aspect of fulfillment that can impact your bottom line. We will provide an overview of typical pricing structures and what to expect, enabling you to budget effectively and make cost-conscious decisions.

Our goal with this guide is to empower e-commerce businesses like yours to make smart, informed decisions about logistics. By understanding the intricacies of e-commerce fulfillment, you can streamline your operations, enhance customer satisfaction, and ultimately drive growth in your business.

What You’ll Learn In This Guide

- What is E-commerce Fulfillment? An Introduction for Growing Businesses

- The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

- Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

- A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

- Core Services Offered by Fulfillment Centers

- How to Choose a Fulfillment Partner: A 6-Point Checklist

- Understanding Fulfillment Pricing: A Breakdown of Common Fees

- Frequently Asked Questions (FAQs) about Fulfillment

- Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

- Important Disclaimer

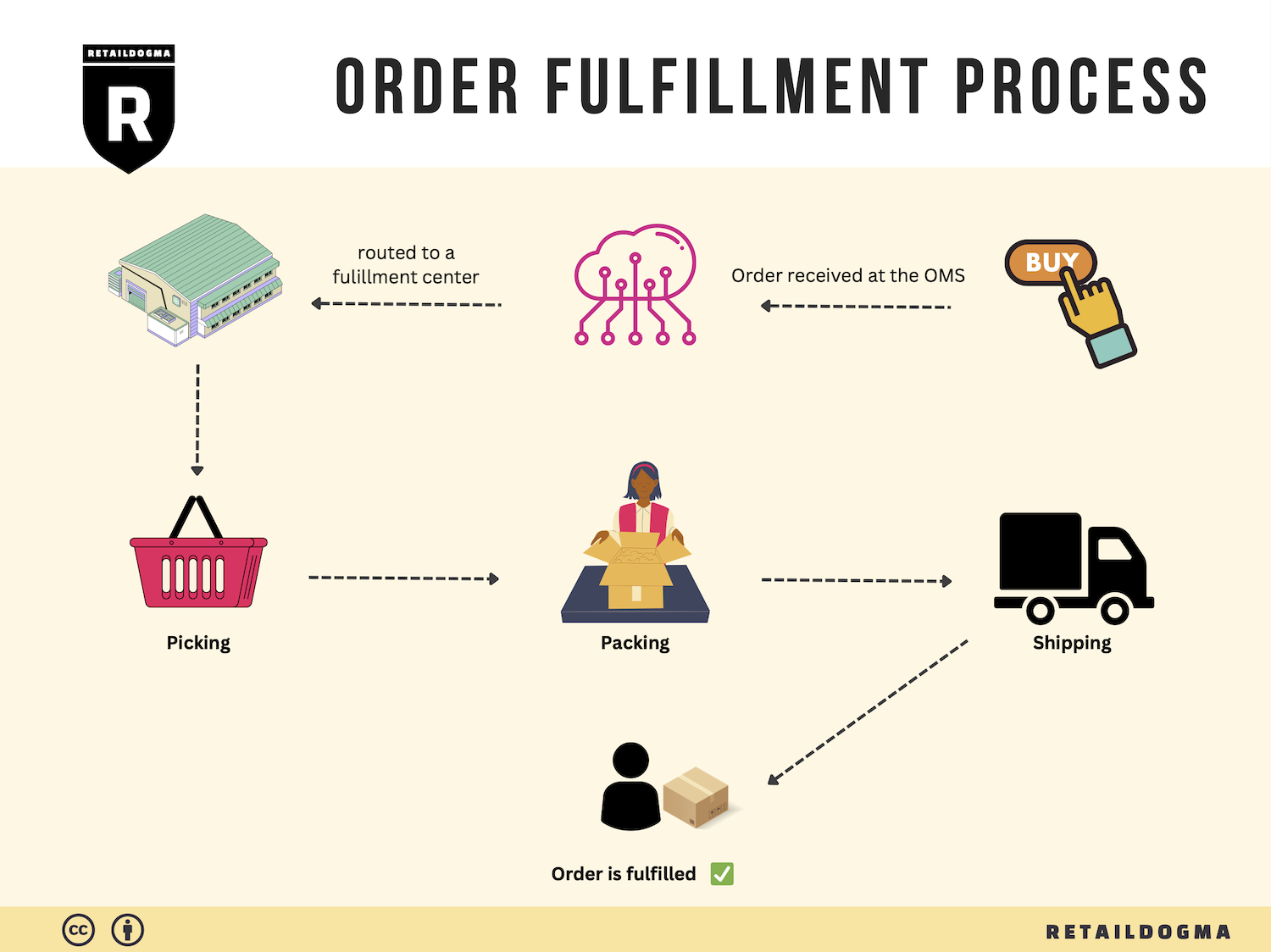

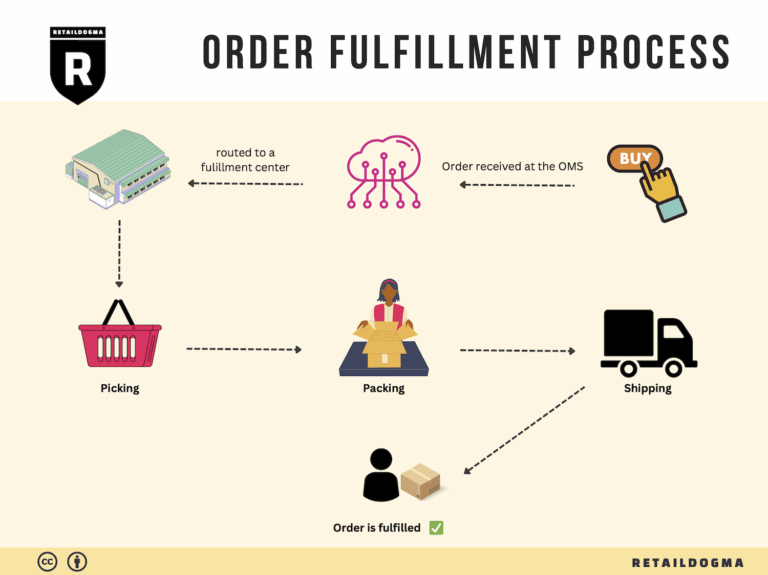

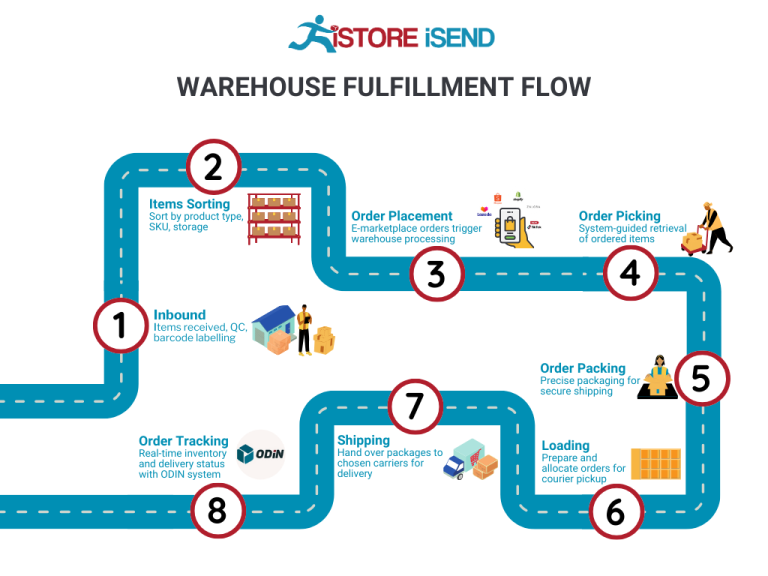

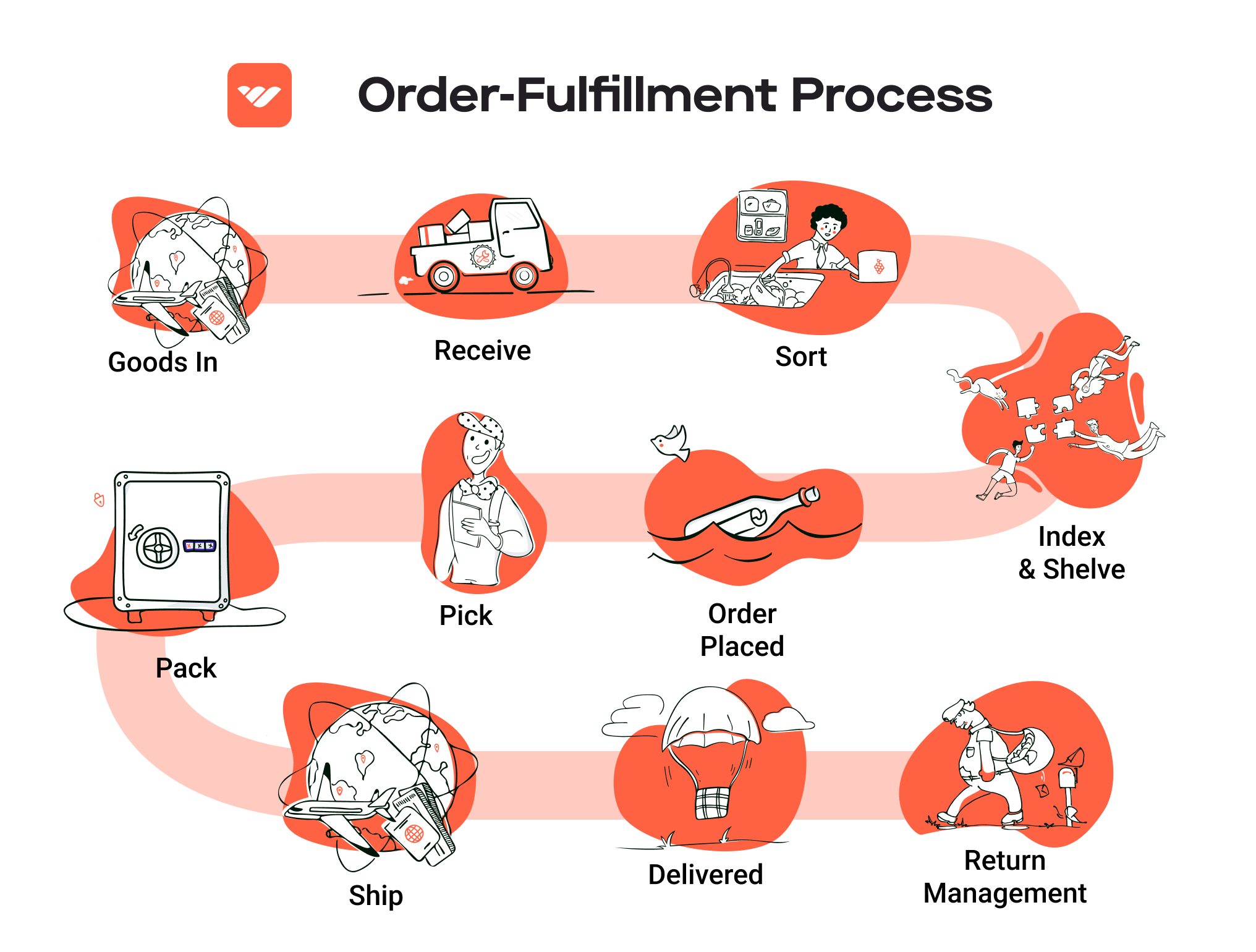

The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

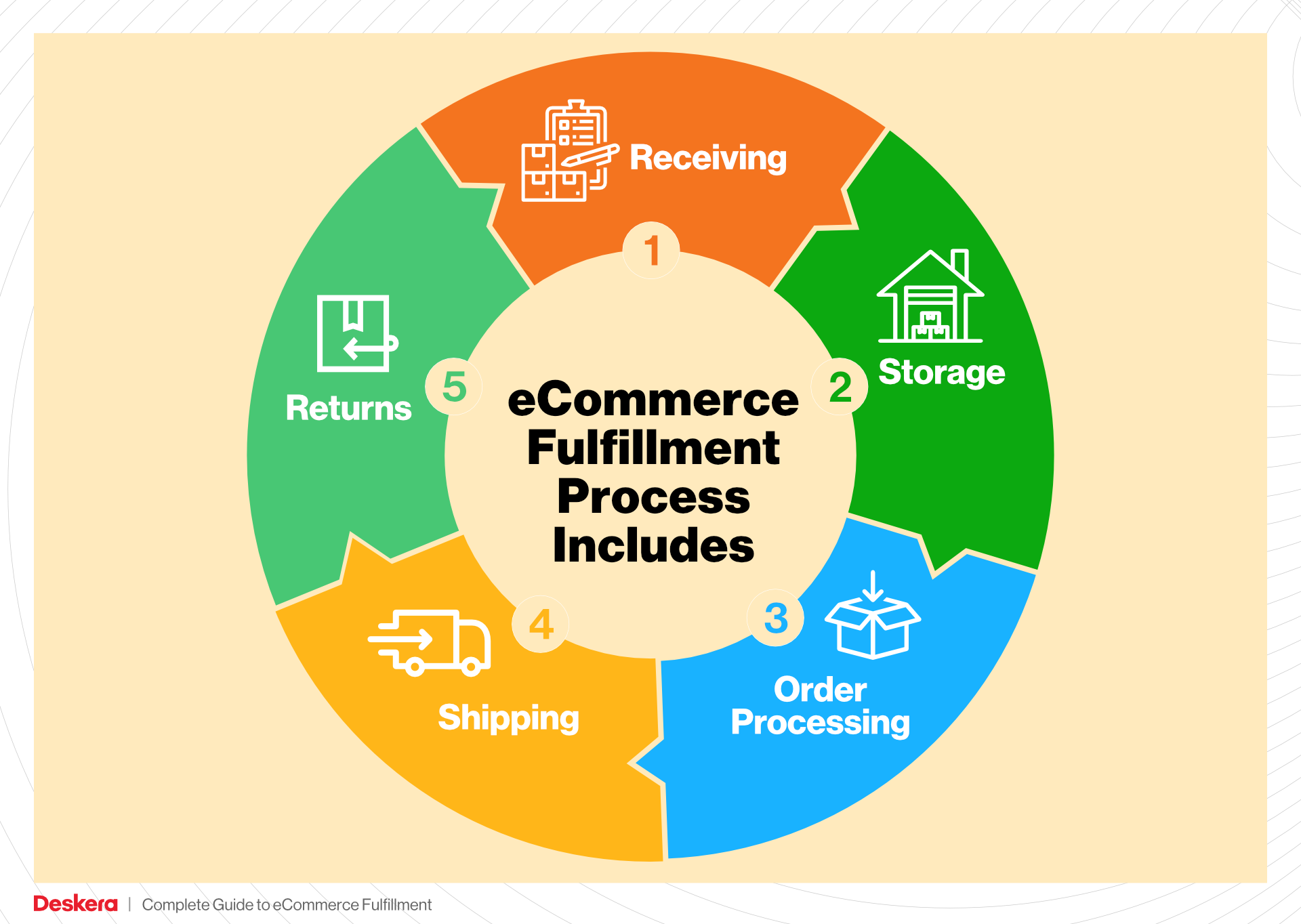

1. Receiving Inventory

The order fulfillment process begins with receiving inventory at the micro-fulfillment center (MFC). During this step, products are delivered from suppliers or manufacturers and checked against purchase orders to ensure accuracy. Each item is assigned a Stock Keeping Unit (SKU), a unique identifier that facilitates tracking and inventory management.

Importance: Proper receiving is crucial as it sets the foundation for the entire fulfillment process. Inaccuracies during this stage can lead to stock discrepancies, which may cause stockouts or overstock situations, affecting customer satisfaction and profitability. Efficient receiving helps businesses maintain an accurate inventory count and ensure that high-demand products are readily available.

2. Warehouse Storage

Once the inventory is received, it is strategically stored within the MFC. The layout of the storage area is optimized for both space efficiency and accessibility, with items stored based on their demand frequency. High-demand products are placed closer to the picking area to expedite the order fulfillment process.

Importance: Effective warehouse storage directly impacts the speed and efficiency of order fulfillment. By organizing products in a logical manner, businesses can reduce the time spent searching for items during the picking process. Utilizing advanced warehouse management systems (WMS) can further enhance this step by providing real-time data on inventory levels and locations, allowing for seamless restocking and inventory management.

3. Order Picking

When a customer places an order, the next step is order picking. This involves retrieving the products from their storage locations based on the order details. A pick list, which outlines the items needed for each order along with their respective SKUs and storage locations, guides the picking process.

Importance: Order picking is a critical phase in the fulfillment process, as it directly influences delivery speed and accuracy. Efficient picking strategies, such as batch picking (where multiple orders are picked simultaneously) or zone picking (where pickers are assigned specific areas), can enhance productivity. The goal is to minimize picking errors and reduce the time it takes to gather items, which is essential for meeting customer expectations for rapid delivery.

4. Order Packing

After items are picked, they move to the packing station, where they are carefully packed for shipment. This step involves checking the picked items against the order to ensure accuracy and then securely packaging them to prevent damage during transit. Packaging materials should be chosen based on the nature of the products, with considerations for sustainability and cost-effectiveness.

Importance: Packing is vital for protecting products and ensuring they arrive at the customer’s door in perfect condition. Proper packing also enhances the unboxing experience for customers, which can influence their perception of the brand. Additionally, using efficient packing methods can optimize shipping costs, as lighter and smaller packages can reduce overall transportation expenses.

5. Shipping & Delivery

The final step in the order fulfillment process is shipping and delivery. Once the orders are packed, they are labeled and sorted based on their destination. This phase includes selecting the most efficient shipping method, whether it be standard, expedited, or same-day delivery, which is facilitated by partnerships with various logistics providers.

Importance: Shipping and delivery are critical in determining customer satisfaction. The speed and reliability of the delivery service can significantly influence repeat business and brand loyalty. In today’s competitive e-commerce landscape, offering multiple delivery options and transparent tracking information is essential for meeting customer expectations. Additionally, optimizing last-mile delivery—often the most expensive and time-consuming part of the logistics process—can enhance overall fulfillment efficiency and reduce costs.

By understanding and optimizing each step of the order fulfillment process, e-commerce businesses can not only improve operational efficiency but also significantly enhance customer satisfaction, setting the stage for sustainable growth and competitive advantage in the marketplace.

Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

Fulfillment Model Comparison

| Model | Who Handles Inventory | Best For (Business Stage) | Key Advantage | Key Disadvantage |

|---|---|---|---|---|

| In-House Fulfillment | Business itself | Established businesses | Full control over inventory and operations | High overhead costs and resource intensive |

| Third-Party Logistics (3PL) | Third-party provider | Growing businesses | Scalability and reduced operational burden | Less control over inventory and processes |

| Dropshipping | Supplier | Startups and small businesses | Low upfront investment and risk | Lower profit margins and dependency on suppliers |

In-House Fulfillment

In-house fulfillment involves managing your own inventory and logistics operations. This model is typically adopted by established businesses that have the resources and infrastructure to handle warehousing, order processing, and shipping internally. The primary advantage of in-house fulfillment is the level of control it provides over inventory management and customer service. Businesses can optimize their operations according to specific needs, ensuring that product quality and delivery standards meet their expectations. Additionally, in-house fulfillment allows for more personalized customer interactions, which can enhance brand loyalty.

However, the disadvantages are significant. Maintaining an in-house fulfillment operation requires substantial investment in warehousing space, technology, and labor. This can lead to high overhead costs, making it less viable for smaller businesses or those with fluctuating order volumes. Moreover, managing logistics can be resource-intensive, diverting focus from core business activities such as marketing and product development. As a business grows, scaling in-house operations can also be challenging, requiring additional capital and management effort.

Third-Party Logistics (3PL)

Third-party logistics (3PL) providers offer a comprehensive solution for businesses looking to outsource their fulfillment operations. This model is particularly suitable for growing businesses that may not have the capacity or desire to manage logistics in-house. 3PL providers handle everything from warehousing and inventory management to order processing and shipping, allowing businesses to focus on their core competencies. The key advantage of using a 3PL is scalability; as order volumes increase, businesses can easily adjust their logistics needs without the burden of managing additional resources.

On the downside, relying on a 3PL means relinquishing some control over inventory and fulfillment processes. This can lead to potential issues with service quality or inventory accuracy, especially if the 3PL does not align with the business’s operational standards. Additionally, businesses may face challenges in communication and coordination with the 3PL provider, which can complicate order management and customer service. While 3PLs can offer cost savings, businesses must carefully evaluate contracts and fees to avoid unexpected expenses.

Dropshipping

Dropshipping is a fulfillment model where the retailer does not keep products in stock but instead transfers customer orders directly to the supplier, who then ships the products directly to the customer. This model is particularly appealing for startups and small businesses with limited resources, as it requires minimal upfront investment and eliminates the need for warehousing and inventory management. The primary advantage of dropshipping is its low financial risk; businesses only purchase products after they’ve made a sale, reducing the burden of unsold inventory.

However, dropshipping comes with its own set of challenges. One of the most significant drawbacks is the lower profit margins, as retailers often pay a premium for the convenience of not handling inventory themselves. Additionally, businesses are heavily reliant on suppliers for product quality and shipping speed, which can lead to customer dissatisfaction if issues arise. Furthermore, managing customer expectations can be complicated when fulfillment times are dictated by third-party suppliers, making it essential for businesses to choose reliable partners and maintain transparent communication with their customers.

In conclusion, each fulfillment model presents unique advantages and disadvantages, making the choice dependent on a business’s specific needs, stage of growth, and operational capabilities. Understanding these models can empower e-commerce business owners to make informed decisions that align with their strategic goals for scaling and customer satisfaction.

A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

Understanding Fulfillment by Amazon (FBA)

Fulfillment by Amazon (FBA) is a service provided by Amazon that allows sellers to store their products in Amazon’s fulfillment centers. Amazon takes care of storage, packaging, and shipping, as well as handling customer service and returns. This service offers e-commerce businesses the opportunity to leverage Amazon’s vast logistics network and customer base, enabling them to focus on other aspects of their business.

How FBA Works

-

Set Up Your FBA Account: Sellers need to create an Amazon seller account and enroll in the FBA program. This involves providing details about the business and agreeing to Amazon’s terms.

-

Product Listing: Once enrolled, sellers list their products on Amazon, indicating that they will use FBA for fulfillment. Each product must comply with Amazon’s guidelines and policies.

-

Shipping Inventory to Amazon: Sellers prepare their products for shipment to Amazon’s fulfillment centers. This includes proper labeling and packaging according to Amazon’s requirements.

-

Storage in Fulfillment Centers: Once received, Amazon stores the inventory in its warehouses. The products are then listed as Prime eligible, making them visible to millions of Amazon Prime members.

-

Order Fulfillment: When a customer places an order for a product listed under FBA, Amazon handles the picking, packing, and shipping of the product. The order is shipped directly from the fulfillment center to the customer.

-

Customer Service and Returns: Amazon also manages customer service inquiries and processes returns for FBA orders, providing a seamless experience for both sellers and customers.

Pros of Using FBA

-

Prime Eligibility: Products fulfilled through FBA are eligible for Amazon Prime, significantly increasing visibility and sales potential. Prime members often prefer Prime-eligible items due to the fast shipping options available.

-

Customer Trust: Amazon is a trusted brand, and using FBA can enhance the credibility of a seller’s products. Customers are more likely to purchase from sellers who utilize FBA due to the assurance of reliable shipping and customer service.

-

Multi-Channel Fulfillment: Sellers can use FBA not only for Amazon orders but also for orders from their own websites or other sales channels. This allows for a unified inventory management system while still offering the benefits of Amazon’s logistics.

-

Simplified Logistics: FBA eliminates the complexities of managing warehousing, packing, and shipping. Sellers can focus on product sourcing, marketing, and other business strategies.

-

Scalability: As sales grow, FBA can easily accommodate increased inventory and order volume without the seller needing to invest in additional warehousing or logistics infrastructure.

-

Global Reach: Sellers can reach international customers through Amazon’s global network, tapping into new markets without the logistics challenges typically associated with global shipping.

Cons of Using FBA

-

High Fees: While FBA provides many benefits, it also comes with various fees, including storage fees for inventory stored in Amazon’s warehouses and fulfillment fees for each order shipped. These costs can accumulate and impact profit margins, especially for low-cost items.

-

Strict Inventory Rules: Amazon enforces strict inventory management policies, including guidelines on how much inventory can be stored and how long it can remain in the fulfillment center. Sellers risk incurring additional fees for excess inventory or for products that do not sell within a certain timeframe.

-

Commingling Risks: FBA often involves commingling inventory, meaning that a seller’s products are stored alongside those of other sellers. This can lead to issues if a customer receives a damaged or counterfeit item, which can reflect poorly on the seller, even if the fault lies with another seller’s inventory.

-

Limited Control Over Fulfillment: Once products are sent to Amazon, sellers have limited control over how their products are handled, packaged, and shipped. Issues such as shipping errors or damages can occur, potentially affecting customer satisfaction and seller ratings.

-

Dependence on Amazon: Using FBA creates a reliance on Amazon’s platform and policies. Changes in Amazon’s rules, fees, or algorithms can significantly affect a seller’s business operations and profitability.

Who is FBA Best For?

Fulfillment by Amazon is particularly beneficial for:

-

Small to Medium-Sized Businesses: Sellers who may not have the resources to manage logistics and fulfillment can leverage FBA’s capabilities to compete with larger retailers.

-

E-commerce Entrepreneurs: New sellers looking to enter the market can use FBA to simplify their logistics and focus on product development and marketing without the burden of fulfillment.

-

Sellers with High Sales Volume: Businesses that have established a steady sales volume can take advantage of FBA’s efficiencies and scale operations without significant overhead costs.

-

Retailers with Seasonal Demand: Businesses that experience fluctuating sales throughout the year can benefit from FBA’s ability to manage inventory without the need for permanent warehousing.

-

Brands Looking to Expand: Companies looking to reach a wider audience or enter new markets can use FBA to facilitate international shipping and improve delivery times.

In conclusion, Fulfillment by Amazon offers a range of advantages that can significantly enhance an e-commerce business’s operational efficiency and market reach. However, it is essential for potential users to carefully weigh the pros and cons to determine if FBA aligns with their business goals and operational capabilities.

Core Services Offered by Fulfillment Centers

Inventory Management & Warehousing

Inventory management and warehousing are foundational services provided by fulfillment centers, encompassing the storage, tracking, and organization of products in a manner that maximizes efficiency and minimizes costs. Fulfillment centers employ advanced inventory management systems that enable real-time tracking of stock levels, which is crucial for e-commerce businesses aiming to maintain optimal inventory levels.

Benefits:

- Improved Accuracy: Automated inventory management systems reduce human error, ensuring accurate stock levels and preventing stockouts or overstock situations.

- Cost Efficiency: By utilizing strategically located warehouses, businesses can decrease transportation costs and optimize their supply chain logistics.

- Scalability: Fulfillment centers provide the flexibility to scale inventory based on demand fluctuations, allowing businesses to adapt quickly to market changes without heavy investment in additional storage space.

- Enhanced Visibility: Advanced reporting tools offer insights into inventory turnover rates and product performance, enabling businesses to make informed decisions regarding purchasing and stocking strategies.

Pick and Pack Services

Pick and pack services involve the process of selecting products from inventory and packaging them for shipment. This service is essential for e-commerce businesses that require efficient and accurate order fulfillment. Fulfillment centers utilize automated systems and trained personnel to ensure that orders are picked accurately and packed securely.

Benefits:

- Speedy Fulfillment: With streamlined pick and pack processes, orders can be processed quickly, allowing businesses to meet customer expectations for fast delivery, including same-day or next-day options.

- Reduced Labor Costs: Automation in the picking and packing process helps minimize labor costs while increasing efficiency, making it easier for businesses to manage fluctuating order volumes.

- Quality Control: Many fulfillment centers implement quality checks during the pick and pack process to ensure that customers receive the correct items in excellent condition, enhancing customer satisfaction.

- Custom Packaging Solutions: Fulfillment centers can offer tailored packaging options that align with a brand’s identity, providing a unique unboxing experience for customers, which can lead to increased brand loyalty.

Kitting and Assembly

Kitting and assembly services involve the grouping of multiple products into a single package or assembling items into a final product before shipment. This service is particularly beneficial for e-commerce businesses that sell bundles or require assembly of products prior to delivery.

Benefits:

- Enhanced Product Offerings: Kitting allows businesses to create unique product bundles that can attract customers and increase average order values. For instance, bundling complementary products encourages upselling.

- Efficiency in Fulfillment: By preparing kits or assembled products ahead of time, fulfillment centers can speed up the order processing time, leading to faster deliveries.

- Cost Savings: Outsourcing kitting and assembly to a fulfillment center can lower overhead costs associated with labor and equipment, allowing businesses to focus resources on core operations.

- Inventory Management: Kitting services can help businesses manage their inventory more effectively by reducing the number of individual SKUs (Stock Keeping Units) they need to track, simplifying their inventory processes.

Returns Management (Reverse Logistics)

Returns management, often referred to as reverse logistics, is a critical service offered by fulfillment centers that streamlines the process of handling product returns from customers. This service ensures that returned items are processed efficiently, whether they are restocked, repaired, or discarded.

Benefits:

- Customer Satisfaction: A smooth returns process enhances customer experience, making it more likely that they will shop with the business again. Clear return policies and efficient processing can build trust and loyalty.

- Cost Control: Effective returns management can help minimize the costs associated with returns, such as shipping and restocking fees, by ensuring that items are processed quickly and accurately.

- Data Insights: Fulfillment centers can provide valuable data on return rates and reasons for returns, enabling businesses to identify trends and make necessary adjustments to their products or processes.

- Inventory Optimization: By efficiently managing returns, fulfillment centers help businesses maintain accurate inventory levels, ensuring that restocked items are available for resale in a timely manner.

In conclusion, the core services provided by fulfillment centers—inventory management and warehousing, pick and pack services, kitting and assembly, and returns management—are essential for e-commerce businesses looking to scale operations effectively. By leveraging these services, businesses can enhance operational efficiency, reduce costs, and ultimately provide a superior customer experience, positioning themselves for sustainable growth in a competitive marketplace.

How to Choose a Fulfillment Partner: A 6-Point Checklist

Location & Warehouse Network

The location of your fulfillment partner’s warehouses is critical for minimizing shipping costs and ensuring timely delivery. A strategically placed network can significantly enhance your logistics efficiency, particularly for last-mile delivery.

Questions to Ask:

– Where are your fulfillment centers located in relation to my target customer base?

– How do you handle shipping and logistics in urban versus rural areas?

– What is your average shipping time to key markets?

– Do you have the ability to open new locations if my business expands?

Technology & Integrations

In the fast-paced world of e-commerce, technology plays a pivotal role in streamlining operations. Your fulfillment partner should offer robust systems that integrate seamlessly with your existing platforms, including e-commerce sites, inventory management, and customer relationship management systems.

Questions to Ask:

– What software and technology platforms do you use for order management and inventory tracking?

– Can your system integrate with my e-commerce platform (e.g., Shopify, WooCommerce)?

– How do you ensure real-time inventory visibility across all channels?

– What data analytics capabilities do you offer to help forecast demand?

Specializations (e.g., Cold Storage, Oversized Items)

Depending on your product line, you may require specific capabilities from your fulfillment partner. Whether you deal in perishables, oversized items, or specialized goods, it’s essential to select a partner who can adequately handle your unique needs.

Questions to Ask:

– What types of products do you specialize in handling?

– Do you have cold storage facilities for perishables? What are the temperature controls?

– How do you manage the storage and fulfillment of oversized or fragile items?

– Can you accommodate seasonal fluctuations in product demand?

Scalability & Capacity

As your business grows, your fulfillment needs will evolve. A suitable partner should have the ability to scale operations to meet your changing requirements, whether that means handling increased order volumes or expanding your geographical reach.

Questions to Ask:

– What is your current capacity for handling orders, and how quickly can you scale up?

– How do you manage peak seasons or unexpected surges in demand?

– Can you provide case studies or examples of how you’ve successfully scaled for other clients?

– What processes do you have in place to handle potential bottlenecks in order fulfillment?

Pricing and Contracts

Understanding the cost structure and contractual obligations of a fulfillment partner is essential for maintaining profitability. Transparency in pricing can help you avoid unexpected fees and ensure that you’re making a sound financial decision.

Questions to Ask:

– What is your pricing model (e.g., per order, per item, subscription-based)?

– Are there any additional fees for storage, handling, or shipping?

– How do you handle pricing adjustments during peak seasons or if my business grows?

– What is the length of the contract, and what are the terms for termination or adjustment?

Customer Support & Reviews

A strong customer support system is invaluable when issues arise. Additionally, reviewing the partner’s reputation through testimonials or case studies can provide insights into their reliability and service quality.

Questions to Ask:

– What type of customer support do you offer (e.g., phone, chat, email)? Are they available 24/7?

– Can you provide references or case studies from current or past clients?

– How do you handle disputes or issues related to order fulfillment?

– What metrics do you use to measure customer satisfaction, and how do you address feedback?

Conclusion

Choosing the right fulfillment partner is crucial for the success of your e-commerce operation. By thoroughly evaluating potential partners against this checklist, you can ensure that you select a provider who not only meets your current needs but can also grow alongside your business. Effective fulfillment strategies are integral to enhancing customer satisfaction and maintaining a competitive edge in the ever-evolving e-commerce landscape.

Understanding Fulfillment Pricing: A Breakdown of Common Fees

Initial Setup Fees

Initial setup fees are often the first costs that e-commerce businesses encounter when partnering with a fulfillment center. These fees can include a variety of services necessary to integrate your inventory into their system. Typically, these costs cover:

- Onboarding Costs: This may include account setup, system integration, and training for your team on using the fulfillment center’s software.

- Inventory Setup: If your products require barcoding or special handling, there may be additional fees for labeling and preparing your inventory for storage.

- Warehouse Configuration: If the fulfillment center needs to adjust its layout to accommodate your products, there could be costs associated with this reconfiguration.

These fees can vary widely based on the complexity of your needs, so it’s essential to clarify what is included in the initial setup before signing a contract.

Receiving Fees

Receiving fees are charged when your inventory arrives at the fulfillment center. This fee typically encompasses the labor required to unload, inspect, and store your goods. Key components of receiving fees include:

- Unloading Costs: The charge for physically unloading the shipment from delivery trucks.

- Inspection Fees: Costs associated with checking the inventory for damages or discrepancies against shipping documents.

- Storage Setup: This may include initial placement into storage bins or shelves.

Receiving fees can be calculated per pallet, box, or item, depending on the fulfillment center’s policies. Understanding how these fees are structured will help you manage your logistics budget more effectively.

Storage Fees (per pallet/bin)

Storage fees are recurring charges for keeping your inventory in the fulfillment center. These fees can be charged monthly, weekly, or even daily, depending on the provider. The calculation of storage fees typically involves:

- Per Pallet/Bin Fee: A flat rate for each pallet or storage bin your inventory occupies. This fee is often based on the size and weight of the items stored.

- Volume-Based Pricing: Some fulfillment centers may use a volume-based model, charging based on the cubic footage your inventory occupies.

It’s crucial to assess your inventory turnover rate when evaluating storage fees. High inventory turnover can mitigate the impact of storage fees, while low turnover can significantly increase costs.

Pick & Pack Fees (per item/order)

Pick & pack fees are charged for the labor involved in retrieving items from storage and preparing them for shipment. This fee is critical for understanding your overall fulfillment costs. Components include:

- Picking Fees: A fee for each item that is picked from the shelf. This can vary based on the complexity of the pick (single item vs. multiple items).

- Packing Fees: A fee for packing the items into boxes, including materials like boxes, bubble wrap, and tape.

Pick & pack fees are usually calculated per order or per item, so it’s essential to estimate your order volume accurately to forecast these expenses.

Shipping Fees

Shipping fees are among the most significant costs associated with fulfillment. These fees are determined by several factors, including:

- Carrier Rates: The cost charged by shipping carriers (e.g., UPS, FedEx, USPS) based on weight, dimensions, and destination.

- Service Level: Expedited shipping options (e.g., next-day delivery) typically incur higher fees than standard shipping.

- Packaging Costs: Additional charges may apply for special packaging requirements, particularly for fragile or oversized items.

Shipping fees can vary significantly based on your fulfillment center’s partnerships with carriers, so understanding these dynamics can lead to cost savings.

Tips for Getting an Accurate Quote

When seeking quotes from fulfillment centers, consider the following tips for obtaining accurate pricing:

- Be Transparent About Your Needs: Clearly communicate your product types, order volumes, and specific fulfillment requirements. This will help the provider offer a more tailored quote.

- Request a Detailed Breakdown: Ask for a breakdown of all potential fees, including those that may not be immediately obvious, such as handling or surcharges.

- Compare Multiple Providers: Don’t settle for the first quote. Compare several fulfillment centers to ensure you’re getting the best value for your specific needs.

- Negotiate Terms: Many fulfillment centers are open to negotiation, especially if you anticipate a high order volume. Discuss potential discounts for long-term contracts or bulk orders.

- Review Hidden Costs: Pay attention to potential hidden costs, such as fees for returns, inventory management, and seasonal surcharges. Understanding the full scope of charges will help you avoid surprises later.

By carefully considering these factors, you can better navigate fulfillment pricing and select a partner that aligns with your business goals.

Frequently Asked Questions (FAQs) about Fulfillment

1. What is micro fulfillment?

Micro fulfillment refers to the strategy of establishing small, localized warehouses—often automated—near urban areas to store and distribute high-demand products. This approach enhances delivery speed and efficiency by minimizing the distance goods travel, allowing for quicker order fulfillment and improved customer satisfaction.

2. How does micro fulfillment benefit e-commerce businesses?

Micro fulfillment provides several advantages, including reduced delivery times, lower shipping costs, better inventory management, and enhanced customer experiences. By decentralizing inventory storage, businesses can respond more swiftly to local demand, reducing stockouts and improving overall operational efficiency.

3. What’s the difference between a warehouse and a fulfillment center?

A warehouse primarily serves as a storage facility for goods, focusing on inventory management and logistics. In contrast, a fulfillment center is specialized for processing orders and shipping them directly to customers. Fulfillment centers often incorporate advanced technology and automation to streamline order processing, while warehouses may not have the same level of operational efficiency.

4. What is a 3PL (Third-Party Logistics Provider)?

A 3PL is a service provider that manages logistics and supply chain operations for businesses. This includes warehousing, transportation, and fulfillment services. Companies often partner with 3PLs to leverage their expertise, technology, and infrastructure, allowing businesses to focus on core activities while improving efficiency and scalability.

5. How much do fulfillment services cost?

The cost of fulfillment services varies based on several factors, including storage space, order volume, picking and packing fees, and shipping methods. Generally, businesses can expect to pay a combination of monthly storage fees per cubic foot, per-order fees, and shipping costs. It’s essential to evaluate different providers and their pricing models to find the best fit for your business needs.

6. Can micro fulfillment centers handle perishables?

Yes, micro fulfillment centers are particularly well-suited for handling perishables. Their proximity to customers allows for quicker order picking and delivery, minimizing the time perishable items spend in transit. This helps maintain product quality and reduces spoilage, making them an ideal choice for grocery and food-related businesses.

7. How do I choose the right location for a micro fulfillment center?

Selecting the right location involves analyzing customer demographics, demand patterns, and proximity to urban centers. Consider areas with high population density and significant online shopping activity. Additionally, assess the availability of suitable real estate, transportation access, and local competition to ensure optimal performance of your micro fulfillment strategy.

8. What technology is commonly used in micro fulfillment centers?

Micro fulfillment centers often utilize advanced technologies such as automation, robotics, and data analytics. Automated systems can assist with inventory management and order fulfillment, while analytics tools help predict demand and optimize stock levels. This technology enhances efficiency and allows for faster, more accurate order processing.

9. How do micro fulfillment centers improve customer satisfaction?

By positioning inventory closer to consumers, micro fulfillment centers enable faster delivery times—often same-day or next-day. This rapid service meets the growing consumer expectation for quick fulfillment, leading to higher customer satisfaction. Additionally, better inventory management reduces stockouts, ensuring that popular items are readily available.

10. Is micro fulfillment a good strategy for small retailers?

Absolutely. Micro fulfillment offers small retailers a competitive advantage by allowing them to provide delivery speeds comparable to larger competitors without the need for extensive logistical resources. It also requires a lower upfront investment, making it easier for smaller businesses to scale operations and adapt to changing market demands.

Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

Evaluating Outsourcing Fulfillment for Your Business

As you consider the best path forward for your e-commerce operations, outsourcing fulfillment can present a compelling opportunity. One of the primary benefits is the significant time savings it offers. By partnering with a fulfillment service, you can delegate the complexities of warehousing, inventory management, and order processing, allowing you to focus on core business activities such as marketing, product development, and customer engagement. This shift not only enhances productivity but also improves your overall operational efficiency.

Scalability is another critical advantage. Fulfillment partners can quickly adjust to your business growth, managing fluctuating order volumes without the need for heavy investment in infrastructure or labor. This flexibility is particularly valuable for e-commerce businesses that experience seasonal spikes in demand or are looking to expand into new markets. With the right fulfillment partner, you can scale your operations smoothly, ensuring that customer expectations for rapid delivery are consistently met.

Moreover, utilizing a fulfillment service provides you access to industry expertise and advanced technology. Many fulfillment centers employ sophisticated inventory management systems and data analytics, allowing for precise demand forecasting and optimized stock levels. This expertise can significantly enhance your supply chain efficiency, reduce stockouts, and improve customer satisfaction.

However, choosing the right fulfillment partner is crucial for sustainable growth. Conduct thorough research to identify providers that align with your business needs, particularly in terms of location, technology, and customer service.

Call to Action

To determine if outsourcing fulfillment is the right next step for your business, take a moment to audit your current shipping processes. Assess your operational bottlenecks, shipping costs, and delivery times. This analysis will provide valuable insights into whether a fulfillment partner can help streamline your operations, enhance your customer experience, and ultimately support your growth ambitions. Start the conversation today and explore how strategic partnerships can elevate your e-commerce success.

Important Disclaimer

⚠️ Important Disclaimer

The information in this guide is for educational purposes. Fulfillment services, pricing, and platform features change frequently. Always conduct your own due diligence and consult with providers directly before making business decisions.