Ecommerce Fulfillment Services: The Ultimate Guide (2025)

What is E-commerce Fulfillment? An Introduction for Growing Businesses

Understanding the Challenges of Order Fulfillment

As an e-commerce business owner, one of the most daunting challenges you may face is managing the logistics of packing and shipping orders. The excitement of growing sales can quickly turn into a logistical nightmare if you find yourself overwhelmed with the sheer volume of orders. Handling inventory, ensuring timely deliveries, and keeping customers satisfied can consume your time and resources, diverting your attention from what truly matters—growing your business.

Defining E-commerce Fulfillment

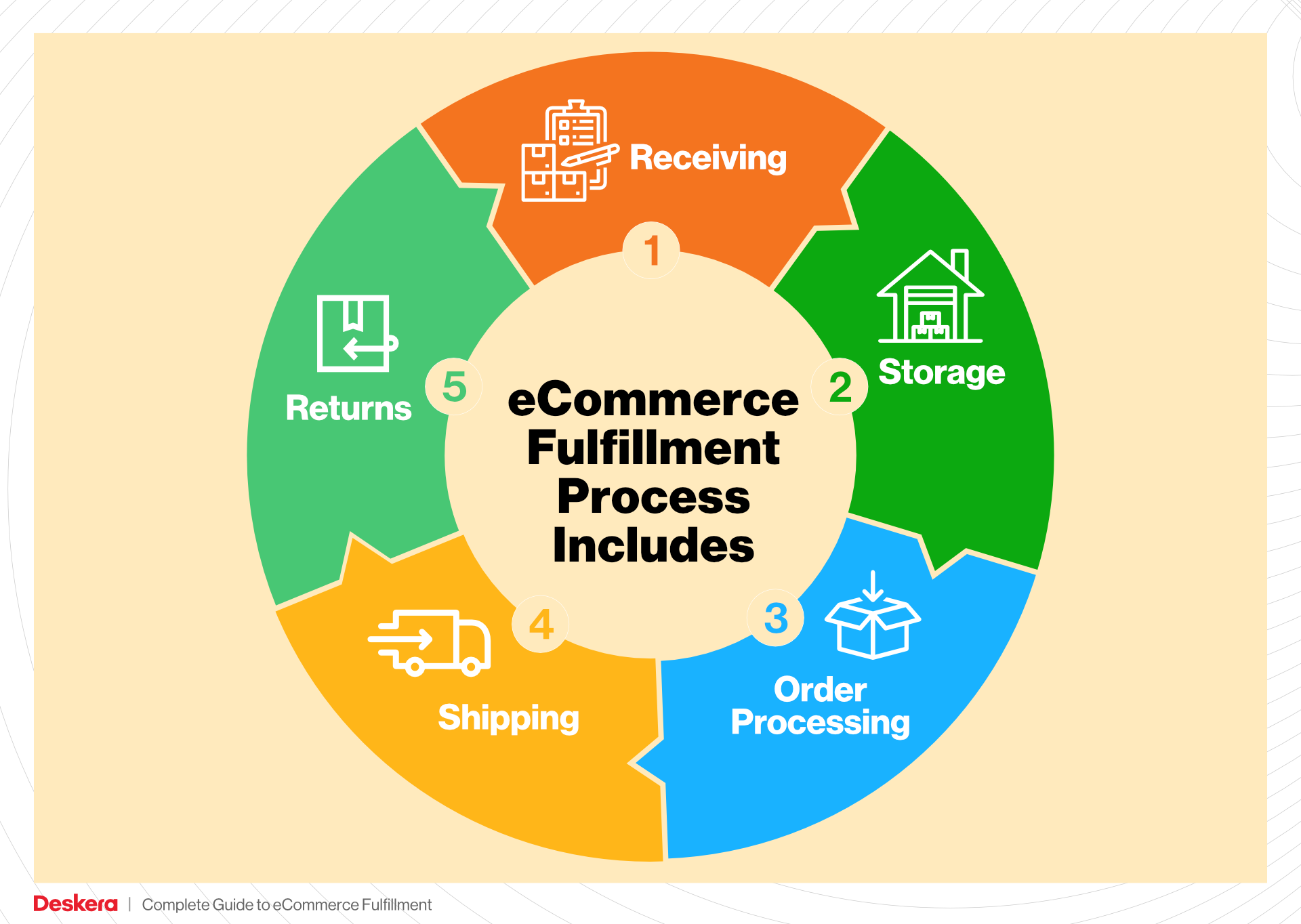

At its core, e-commerce fulfillment is the comprehensive process of getting a product from your inventory into the hands of your customer. This involves several critical steps: receiving inventory, storing it efficiently, processing orders, picking the correct items, packing them securely, and finally, shipping them out to customers. The efficiency of this process can significantly impact your business’s reputation and bottom line.

What This Guide Covers

In this guide, we will explore various e-commerce fulfillment models that can help streamline your logistics. You’ll learn about:

- Fulfillment by Amazon (FBA): A service that allows you to leverage Amazon’s extensive logistics network to handle your shipping and customer service.

- Third-Party Logistics (3PL): Partnering with a specialized provider that manages your fulfillment needs, allowing you to focus on scaling your business.

- Core Services: The essential functions of fulfillment centers, including inventory management, pick and pack services, and shipping logistics.

Additionally, we’ll provide insights on how to choose the right fulfillment partner for your business. Key considerations will include location, service offerings, scalability, and technology integration to ensure seamless operations. Lastly, we’ll touch upon pricing models to help you understand the financial implications of different fulfillment options.

Empowering Your Business Decisions

The ultimate goal of this guide is to empower you, the business owner, to make informed decisions about your logistics strategy. By understanding the nuances of e-commerce fulfillment and the various options available, you can select the right partner that aligns with your business goals and customer expectations. This strategic move will not only enhance operational efficiency but also contribute to your overall growth and success in the competitive e-commerce landscape.

What You’ll Learn In This Guide

- What is E-commerce Fulfillment? An Introduction for Growing Businesses

- The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

- Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

- A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

- Core Services Offered by Fulfillment Centers

- How to Choose a Fulfillment Partner: A 6-Point Checklist

- Understanding Fulfillment Pricing: A Breakdown of Common Fees

- Frequently Asked Questions (FAQs) about Fulfillment

- Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

- Important Disclaimer

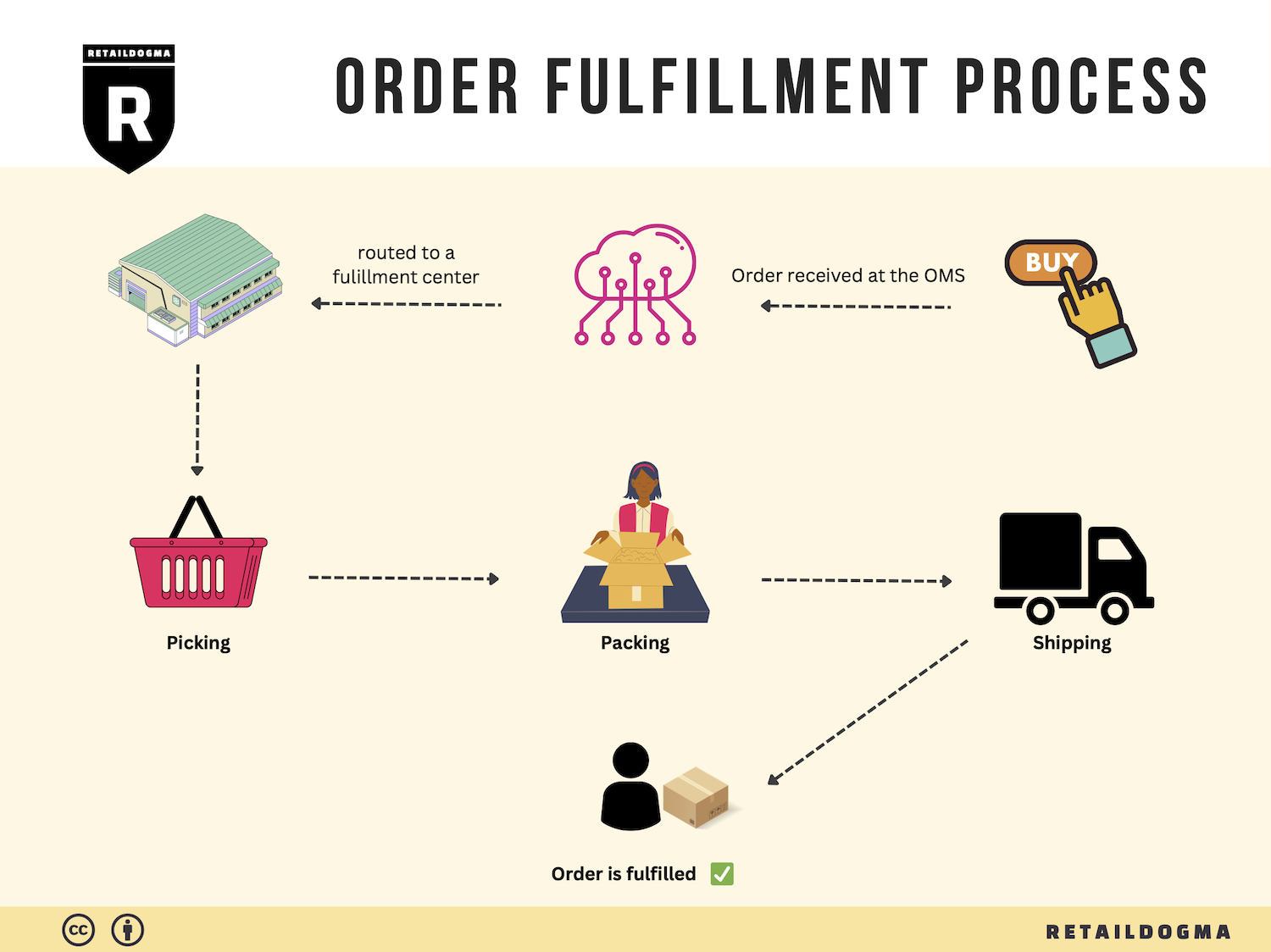

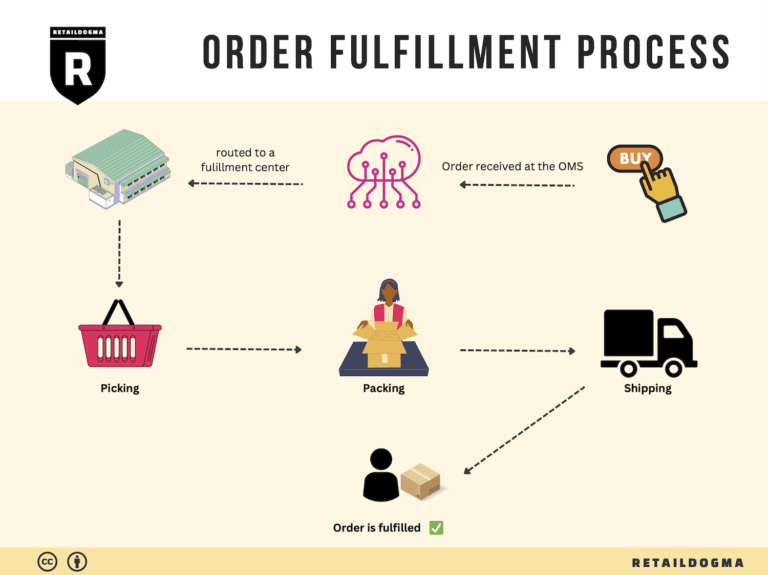

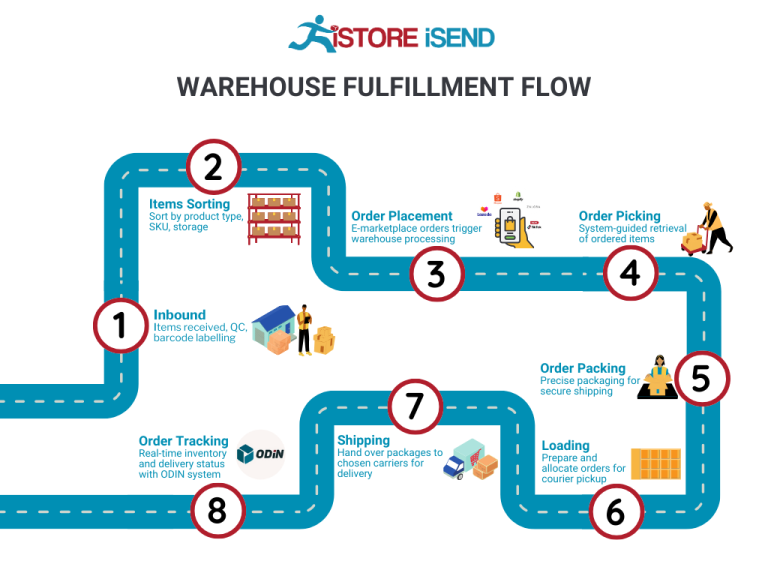

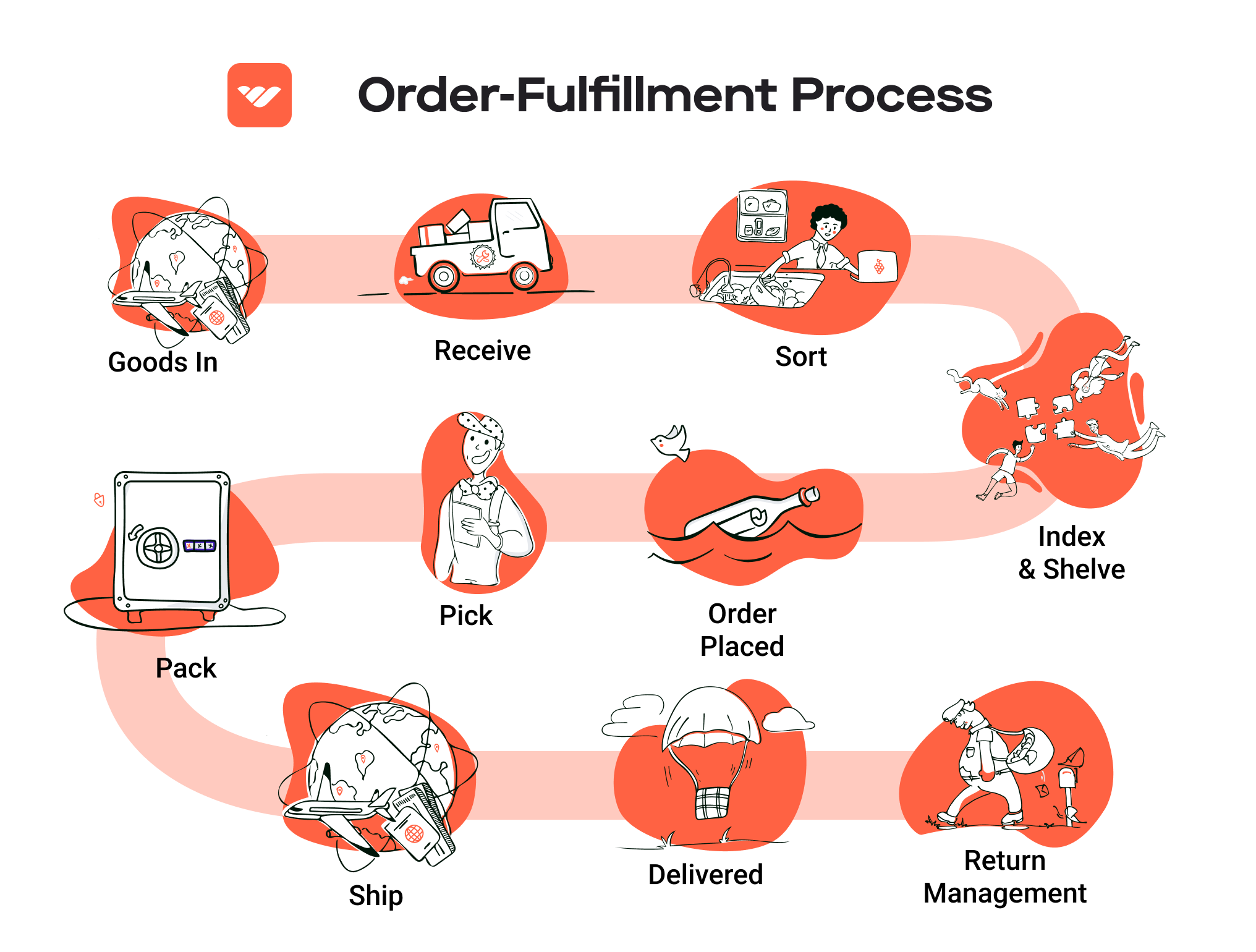

The Order Fulfillment Process: From ‘Buy’ Button to Customer’s Door

1. Receiving Inventory

The order fulfillment process begins with receiving inventory at the fulfillment center. When products arrive from manufacturers or suppliers, they must be carefully checked and logged into the system. This process involves inspecting the items for quality and accuracy against the purchase order. Each product is assigned a Stock Keeping Unit (SKU), a unique identifier that helps in tracking inventory throughout the fulfillment process.

Importance: Proper inventory receiving is crucial because it ensures that the right products are available for future orders. Any discrepancies at this stage can lead to stockouts or overstock situations, which can negatively impact customer satisfaction and operational efficiency.

Key Term: SKU (Stock Keeping Unit) – A unique identifier for each product that facilitates tracking and inventory management.

2. Warehouse Storage

Once the inventory is received, the next step is efficient storage within the fulfillment center. Products are organized and stored in designated areas, often categorized by type, size, or sales velocity. Advanced warehouse management systems (WMS) are employed to optimize storage layout and ensure easy access to items.

Importance: Proper storage solutions minimize retrieval time and help maintain an organized warehouse. Efficient space utilization can lead to significant cost savings and faster order processing, as items can be located quickly.

Key Term: Warehouse Management System (WMS) – Software that helps manage inventory levels, storage locations, and order processing within the warehouse.

3. Order Picking

When a customer places an order, the fulfillment center moves to the order picking stage. Staff or automated systems generate pick lists that specify the items needed for each order. This process involves locating the items in the warehouse and preparing them for packing. Depending on the fulfillment center’s technology, this may include manual picking, where workers physically retrieve items, or automated picking systems that use robotics.

Importance: Efficient order picking is vital for meeting customer expectations regarding delivery speed and accuracy. Delays or mistakes in this phase can lead to customer dissatisfaction and increased return rates.

Key Term: Pick List – A document or digital list that indicates the items that need to be picked for an order, often organized by location within the warehouse for efficiency.

4. Order Packing

Once the items are picked, they are moved to the packing station. Here, items are carefully packaged to ensure they arrive at the customer’s door in perfect condition. This stage often involves selecting the appropriate box size, adding protective materials (such as bubble wrap or packing peanuts), and generating shipping labels. Some fulfillment centers may also offer branded packaging options to enhance the customer experience.

Importance: Proper packing is essential not only for protecting the product during transit but also for creating a positive impression on the customer. Well-packaged orders can lead to repeat business and positive reviews.

Key Term: Packing Slip – A document included in the package that lists the items contained within, often used for order verification by the customer.

5. Shipping & Delivery

The final step in the order fulfillment process is shipping and delivery. Once the order is packed, it is handed over to a shipping carrier such as UPS, FedEx, or USPS. Fulfillment centers often have established relationships with multiple carriers, allowing them to choose the most efficient and cost-effective shipping method. Real-time tracking information is usually provided to customers so they can monitor their order’s journey.

Importance: Timely shipping and delivery are critical for customer satisfaction. In today’s competitive e-commerce landscape, customers expect fast and reliable delivery options. The ability to offer various shipping speeds (including same-day or two-day shipping) can be a significant competitive advantage.

Key Term: Shipping Carrier – A company that transports packages and freight, responsible for the physical delivery of orders to customers.

By mastering each step of the order fulfillment process, e-commerce businesses can significantly enhance their operational efficiency and improve customer satisfaction, ultimately leading to increased sales and growth.

Comparing Fulfillment Models: In-House vs. 3PL vs. Dropshipping

Fulfillment Models Comparison

| Model | Who Handles Inventory | Best For (Business Stage) | Key Advantage | Key Disadvantage |

|---|---|---|---|---|

| In-House Fulfillment | Business Owner | Startups and Established Brands | Complete control over inventory and processes | High overhead costs and resource-intensive |

| Third-Party Logistics (3PL) | Third-Party Provider | Growing Businesses | Scalability and reduced operational burden | Less control over inventory and fulfillment speed |

| Dropshipping | Supplier | New Entrepreneurs and Small Brands | Low upfront investment and minimal risk | Lower margins and dependency on suppliers |

In-House Fulfillment

In-house fulfillment involves managing all logistics operations within your own facilities. This model allows business owners to retain complete control over inventory management, order processing, and shipping. Companies that adopt in-house fulfillment typically invest in warehousing space, hire staff, and use software to streamline their operations. This model is often favored by startups that want to maintain tight control over their products and customer experience. The key advantage is the ability to directly oversee every aspect of the fulfillment process, allowing for quick adjustments based on customer feedback or operational needs. However, this model can lead to high overhead costs, including labor, storage, and equipment, which may strain resources, especially for smaller businesses. Additionally, the time and effort required to manage logistics can distract from core business activities such as marketing and sales.

Third-Party Logistics (3PL)

Third-party logistics (3PL) providers offer outsourced fulfillment services, handling inventory storage, order processing, and shipping for multiple businesses. This model is particularly beneficial for growing companies that need to scale operations without the burden of managing logistics themselves. 3PL providers often come equipped with advanced technology and established relationships with shipping carriers, allowing businesses to benefit from discounted shipping rates and faster delivery times. The primary advantage of using a 3PL is the scalability it offers; businesses can easily adjust their fulfillment capabilities as they grow without needing to invest heavily in infrastructure. However, a key disadvantage is the reduced control over inventory and fulfillment speed. When relying on a third party, businesses must trust that the provider will meet their standards for order accuracy and delivery times, which can vary significantly between providers.

Dropshipping

Dropshipping is a fulfillment model where the retailer does not hold any inventory. Instead, when a customer makes a purchase, the retailer forwards the order to a supplier who ships the product directly to the customer. This model is especially attractive to new entrepreneurs and small businesses, as it requires minimal upfront investment and significantly lowers the financial risk associated with holding inventory. The key advantage of dropshipping is the ability to start an e-commerce business with very low overhead costs, allowing entrepreneurs to focus on marketing and customer acquisition rather than logistics. However, dropshipping also presents challenges, such as lower profit margins due to reliance on suppliers for fulfillment. Additionally, businesses are dependent on their suppliers for inventory management and shipping, which can lead to inconsistencies in product availability and delivery times. This lack of control can result in customer dissatisfaction if the supplier fails to meet expectations.

Conclusion

Each fulfillment model presents unique advantages and challenges that must be carefully considered based on your business’s current stage and long-term goals. In-house fulfillment may be ideal for startups that value control and customization but can become resource-intensive. Third-party logistics offer scalability and reduced operational burdens, making them suitable for growing businesses, while dropshipping provides a low-risk entry point for new entrepreneurs. Understanding these models will empower e-commerce business owners to make informed decisions that align with their operational needs and growth strategies.

A Deep Dive into Amazon FBA: Pros, Cons, and Who It’s For

Understanding Fulfillment by Amazon (FBA)

Fulfillment by Amazon (FBA) is a service provided by Amazon that allows sellers to store their products in Amazon’s fulfillment centers. Amazon then takes care of storage, packaging, shipping, and customer service on behalf of the sellers. This model has transformed how e-commerce businesses operate, enabling them to scale rapidly without investing heavily in logistics and warehousing.

How FBA Works

When a seller enrolls in the FBA program, they send their inventory to Amazon’s fulfillment centers. Here’s a step-by-step breakdown of the FBA process:

-

Inventory Shipment: Sellers prepare their products according to Amazon’s guidelines and ship them to designated Amazon fulfillment centers.

-

Storage: Once the inventory arrives, Amazon stores it in its warehouses. The products are organized and cataloged for easy retrieval.

-

Order Processing: When a customer places an order for a product listed as FBA, Amazon’s system automatically processes the order. This includes picking the item from storage, packing it securely, and preparing it for shipment.

-

Shipping: Amazon handles the shipping process, utilizing its extensive logistics network. Orders are typically shipped using Amazon’s delivery services, which can include options for same-day or two-day delivery.

-

Customer Service: Amazon provides customer service for FBA orders, managing inquiries and returns, which alleviates the burden on sellers.

-

Payment: After the sale, Amazon deducts its fees and deposits the remaining balance into the seller’s account.

Pros of Using FBA

-

Prime Eligibility: Products fulfilled by Amazon are eligible for Amazon Prime, which can significantly increase sales. Prime members often prioritize products that offer fast, free shipping.

-

Customer Trust: Leveraging Amazon’s brand reputation can enhance customer trust. Many consumers prefer purchasing from sellers using FBA because they associate the service with reliability and quality.

-

Multi-Channel Fulfillment: FBA allows sellers to fulfill orders from other sales channels (like their own websites or eBay) using Amazon’s fulfillment network. This means sellers can streamline their logistics across multiple platforms while benefiting from Amazon’s efficiency.

-

Scalability: FBA provides businesses with the ability to scale quickly. Sellers can focus on marketing and product development while Amazon manages the logistics and fulfillment.

-

Inventory Management: Amazon provides tools for inventory tracking and management, helping sellers monitor stock levels and sales trends effectively.

Cons of Using FBA

-

High Fees: FBA comes with various fees, including storage fees and fulfillment fees. These costs can accumulate, especially for sellers with low-margin products or large inventories.

-

Strict Inventory Rules: Amazon has stringent guidelines regarding inventory management, packaging, and shipping. Non-compliance can lead to penalties or removal from the FBA program.

-

Commingling Risks: FBA products may be commingled with similar items from other sellers. This means that when a customer orders a product, they may receive an item that is not specifically theirs, which can lead to quality control issues and brand reputation concerns.

-

Limited Control: Sellers have limited control over the fulfillment process. They must rely on Amazon’s systems and processes, which may not always align with their business practices or customer service expectations.

-

Inventory Limitations: Amazon imposes restrictions on how much inventory a seller can send to FBA, particularly during peak seasons. This can hinder a seller’s ability to meet demand.

Who is FBA Best For?

Fulfillment by Amazon is ideal for a variety of sellers but is particularly beneficial for:

-

Small to Medium-Sized Businesses: These businesses often lack the resources to manage their logistics efficiently. FBA allows them to compete with larger sellers by providing access to Amazon’s extensive logistics network.

-

E-commerce Entrepreneurs: New sellers can leverage FBA to enter the market without significant upfront investments in warehousing and fulfillment.

-

Businesses with High Sales Volume: Sellers who expect high order volumes can benefit from the scalability of FBA, allowing them to handle peak demand without additional overhead.

-

Brands Seeking Increased Visibility: Companies looking to enhance their brand presence and trust can benefit from the credibility associated with Amazon’s fulfillment services.

-

Multi-Channel Sellers: Those selling across multiple platforms can streamline their operations by using FBA to fulfill orders from various sales channels.

In conclusion, while FBA offers numerous advantages that can facilitate growth and operational efficiency, it is crucial for sellers to weigh the pros and cons carefully. Understanding how FBA aligns with their business goals will help e-commerce entrepreneurs make informed decisions on whether to leverage Amazon’s fulfillment capabilities.

Core Services Offered by Fulfillment Centers

Inventory Management & Warehousing

Inventory management and warehousing are foundational services provided by fulfillment centers. This process involves the receipt, organization, and storage of products until they are ready to be shipped to customers. Fulfillment centers utilize advanced inventory management systems that offer real-time tracking of stock levels, ensuring that businesses can maintain optimal inventory levels and reduce the risks of overstocking or stockouts.

For e-commerce businesses, effective inventory management translates directly into enhanced operational efficiency. By outsourcing these tasks to a fulfillment center, businesses can benefit from:

- Reduced Overhead Costs: Fulfillment centers often have established systems and protocols that can handle large volumes of inventory without the need for a business to invest in expensive warehousing solutions.

- Improved Accuracy: Automated inventory tracking minimizes human error, ensuring that businesses have a clear view of their stock, which is crucial for maintaining customer satisfaction.

- Scalability: As an e-commerce business grows, a fulfillment center can easily accommodate increased inventory levels, allowing for seamless scaling without the need for significant infrastructure changes.

Pick and Pack Services

Once an order is placed, the pick and pack services come into play. This service involves selecting the ordered items from inventory (picking) and packaging them for shipment (packing). Fulfillment centers employ trained staff and, in many cases, automated systems to ensure that orders are processed quickly and accurately.

The benefits of utilizing pick and pack services include:

- Efficiency: Fulfillment centers streamline the picking and packing process through optimized layouts and technology, which can significantly reduce the time from order placement to shipping.

- Accuracy: With the implementation of barcoding and scanning technologies, the likelihood of shipping errors is minimized, leading to higher customer satisfaction and lower return rates.

- Customization: Many fulfillment centers offer customizable packing options, allowing businesses to enhance their brand image through personalized packaging. This can include branded boxes, thank you notes, or promotional materials, which help improve customer experience and retention.

Kitting and Assembly

Kitting and assembly services are essential for e-commerce businesses that offer bundled products or require items to be assembled before shipping. This service involves taking individual items and grouping them into a single kit or assembling them into a finished product. Fulfillment centers have the resources and expertise to handle these tasks efficiently.

The advantages of kitting and assembly services include:

- Streamlined Operations: By outsourcing kitting and assembly, businesses can reduce the complexity of their operations, allowing them to focus on core functions such as marketing and sales.

- Cost-Effective Solutions: Fulfillment centers can often perform kitting and assembly at a lower cost than in-house efforts due to economies of scale and specialized labor.

- Faster Time-to-Market: With efficient kitting and assembly processes, businesses can bring new products to market more quickly, responding to customer demands and trends in real-time.

Returns Management (Reverse Logistics)

Returns management, also known as reverse logistics, is a critical service offered by fulfillment centers. This process involves handling product returns from customers, including assessing the condition of returned items, restocking, and managing refunds or exchanges. A well-structured returns management process can significantly enhance customer satisfaction and loyalty.

The benefits of effective returns management include:

- Customer Retention: A smooth returns process fosters trust and confidence in a brand. Customers are more likely to make purchases if they know they can return items easily.

- Cost Management: Fulfillment centers streamline the returns process, reducing the time and costs associated with handling returns in-house. This efficiency can lead to better inventory management and fewer losses from unsold returned items.

- Data Insights: By analyzing return data, businesses can gain valuable insights into customer preferences and product performance. This information can inform future product development and inventory decisions, ultimately leading to improved sales and reduced return rates.

In conclusion, partnering with a fulfillment center provides e-commerce businesses with a robust framework for managing logistics, improving efficiency, and enhancing customer satisfaction. By leveraging core services like inventory management, pick and pack, kitting and assembly, and returns management, businesses can scale effectively while focusing on their primary objectives of growth and customer engagement.

How to Choose a Fulfillment Partner: A 6-Point Checklist

Location & Warehouse Network

Why It’s Important:

The geographical location of your fulfillment partner’s warehouses plays a crucial role in shipping efficiency and cost-effectiveness. A strategically located fulfillment center can significantly reduce transit times and shipping costs, enhancing customer satisfaction.

Questions to Ask:

– Where are your fulfillment centers located, and how do they align with my customer demographics?

– What is your average shipping time to key markets?

– Do you have a network of warehouses that allows for regional distribution?

Technology & Integrations

Why It’s Important:

In the eCommerce landscape, technology is pivotal for managing inventory, processing orders, and tracking shipments. A fulfillment partner that utilizes advanced warehouse management systems (WMS) can offer real-time data, improve accuracy, and streamline operations.

Questions to Ask:

– What technology platforms do you use for inventory management and order processing?

– Can your system integrate with my eCommerce platform (e.g., Shopify, WooCommerce, Amazon)?

– How do you handle inventory visibility and tracking? Can I access real-time updates?

Specializations (e.g., Cold Storage, Oversized Items)

Why It’s Important:

Depending on your product offerings, you may require specific handling capabilities. Whether you sell perishable goods, oversized items, or fragile products, ensuring your fulfillment partner has the right facilities and expertise is essential for maintaining product integrity.

Questions to Ask:

– Do you have specialized facilities for handling specific types of products (e.g., cold storage, hazardous materials)?

– What processes do you have in place for managing unique inventory requirements?

– Can you accommodate seasonal fluctuations in product type or volume?

Scalability & Capacity

Why It’s Important:

As your business grows, your fulfillment needs will evolve. A partner that can scale operations in response to increased demand will prevent bottlenecks and ensure consistent service quality.

Questions to Ask:

– How do you handle increases in order volume during peak seasons?

– What is your current capacity, and how quickly can you scale up if needed?

– Are there any limitations on the types or volumes of products you can handle?

Pricing and Contracts

Why It’s Important:

Understanding the pricing structure and contractual obligations is vital for budget management and avoiding unexpected costs. Transparency in pricing can help you make informed decisions and maintain profitability.

Questions to Ask:

– What is your pricing model (e.g., per order, per item, storage fees)?

– Are there any additional costs I should be aware of (e.g., for returns processing, packaging)?

– What are the terms of your contract, and how do you handle contract renewals or changes?

Customer Support & Reviews

Why It’s Important:

Effective communication and support are critical in maintaining a smooth fulfillment operation. A partner with a strong customer support system can address issues quickly, ensuring that your customers remain satisfied.

Questions to Ask:

– What support channels do you offer (e.g., phone, email, live chat)?

– How do you handle customer service issues that arise from fulfillment errors?

– Can you provide references or case studies from other businesses similar to mine?

Conclusion

Choosing the right fulfillment partner is a significant decision that can impact your eCommerce business’s efficiency and customer satisfaction. By following this checklist and asking the right questions, you can evaluate potential partners more effectively and select one that aligns with your business goals. Remember, a fulfilling partnership is not just about logistics; it’s about building a relationship that supports your growth and success.

Understanding Fulfillment Pricing: A Breakdown of Common Fees

Initial Setup Fees

Initial setup fees are one-time charges incurred when you first partner with a fulfillment center. These fees can cover various aspects of onboarding, such as account creation, system integration, and the initial setup of your inventory. The complexity of your e-commerce platform and the extent of customization required can influence the cost.

For instance, if you need the fulfillment center to integrate with your existing e-commerce platform (like Shopify or WooCommerce), this could add to the setup costs. Typically, initial setup fees can range from a few hundred to several thousand dollars, depending on the provider and the services included. To mitigate these costs, inquire about bundled services or discounts for longer contracts.

Receiving Fees

Receiving fees are charged each time your products arrive at the fulfillment center. This fee compensates the center for the labor involved in unloading, inspecting, and cataloging your inventory.

Calculating receiving fees usually depends on the volume of products being received. Many fulfillment centers will charge a flat fee per pallet or per item. For example, a center might charge $25 per pallet or $0.50 per item. If you’re shipping large quantities frequently, negotiate a bulk receiving rate to keep costs manageable.

Storage Fees (per pallet/bin)

Storage fees are recurring charges for keeping your inventory at the fulfillment center. This fee is generally calculated on a monthly basis and can be charged per pallet, bin, or cubic foot.

For example, a fulfillment center may charge $10 per pallet per month or $0.75 per cubic foot. The total storage fee will depend on how much space your inventory occupies. It’s essential to keep track of your inventory turnover rate; slow-moving items can lead to increased storage costs. To optimize your storage expenses, consider implementing just-in-time inventory practices or negotiating tiered pricing based on volume.

Pick & Pack Fees (per item/order)

Pick and pack fees are charged for the labor involved in retrieving items from storage and packing them for shipment. This fee is typically calculated per item or per order, depending on the complexity of the packing requirements.

For instance, a fulfillment center might charge $1.00 per item for picking and packing or a flat fee of $3.00 per order, regardless of the number of items. If your products require special handling or custom packaging, this could also affect the pricing. To minimize pick and pack fees, consider optimizing your inventory mix to include fewer SKUs or negotiate a flat-rate service for high-volume orders.

Shipping Fees

Shipping fees are the costs associated with dispatching your orders to customers. These fees can vary significantly based on the shipping method chosen, the carrier used, and the destination of the package.

Fulfillment centers often have partnerships with major carriers, allowing them to offer discounted shipping rates. Shipping fees are typically calculated based on weight, dimensions, and destination. For example, a fulfillment center may charge $5 for a standard shipping rate for a package weighing under 2 lbs within the same region. To control shipping costs, assess your shipping options frequently, and consider leveraging the fulfillment center’s bulk shipping rates.

Tips for Getting an Accurate Quote

To ensure you receive an accurate quote from a fulfillment center, consider the following tips:

-

Be Specific: Provide detailed information about your product types, volumes, and any special handling requirements. The more information you provide, the more tailored the quote will be.

-

Ask About All Fees: Inquire about all potential fees, including hidden or ancillary costs such as return handling, packaging materials, and customer service charges.

-

Negotiate Terms: Don’t hesitate to negotiate terms, especially if you anticipate high order volumes. Some fulfillment centers may offer discounts for long-term contracts or increased order sizes.

-

Request a Trial Period: If possible, negotiate a trial period to evaluate the fulfillment center’s performance and costs before committing to a long-term contract.

-

Compare Multiple Providers: Get quotes from several fulfillment centers to understand the market rates and find the best fit for your business needs.

By understanding these common fees and how they are calculated, you can better assess potential fulfillment partners and make informed decisions that align with your business goals.

Frequently Asked Questions (FAQs) about Fulfillment

1. What is Amazon Fulfillment and how does it work?

Amazon Fulfillment refers to the process by which Amazon handles storage, packaging, and shipping of products for sellers through its Fulfillment by Amazon (FBA) program. Sellers send their products to Amazon’s fulfillment centers, where Amazon takes care of inventory management, order processing, and customer service, allowing sellers to focus on growing their business.

2. How can I find an Amazon fulfillment center near me?

To locate an Amazon fulfillment center in your area, you can visit the Amazon Jobs website and search for fulfillment center locations. Additionally, using Google Maps or other mapping services to search for “Amazon fulfillment center near me” can help you identify nearby facilities.

3. What’s the difference between a warehouse and a fulfillment center?

While both warehouses and fulfillment centers store products, their functions differ significantly. A warehouse primarily focuses on long-term storage and bulk distribution, while a fulfillment center actively processes orders, including picking, packing, and shipping items, to ensure faster delivery to customers.

4. What is a 3PL (Third-Party Logistics) provider?

A 3PL provider is a company that offers outsourced logistics services, including warehousing, inventory management, order fulfillment, and shipping. Businesses partner with 3PLs to streamline their logistics operations, reduce overhead costs, and leverage the provider’s expertise in supply chain management.

5. How much do fulfillment services cost?

The cost of fulfillment services can vary widely based on several factors, including the size and weight of products, order volume, storage space required, and additional services like returns processing or custom packaging. Typically, costs may include a per-order fee, storage fees, and shipping charges. It’s essential to request quotes from multiple fulfillment centers to compare pricing and services.

6. What are the benefits of using Amazon Fulfillment services?

Using Amazon Fulfillment services provides numerous benefits, including:

– Access to Amazon’s vast logistics network: This ensures quick delivery times and reliability.

– Increased visibility: Products listed through FBA are often prioritized in search results on Amazon.

– Customer service support: Amazon handles customer inquiries and returns, allowing sellers to focus on their core business.

– Discounted shipping rates: Leveraging Amazon’s shipping partnerships can reduce overall shipping costs.

7. How does the order fulfillment process work at Amazon?

The order fulfillment process at Amazon typically involves the following steps:

1. Receiving Inventory: Sellers ship their products to Amazon fulfillment centers.

2. Storage and Organization: Products are stored in an organized manner for efficient retrieval.

3. Picking and Packing: When an order is placed, Amazon staff pick the items and pack them securely.

4. Shipping: Orders are shipped via Amazon’s logistics network, often with options for same-day or two-day delivery.

8. Can I use Amazon Fulfillment for my small business?

Yes, Amazon Fulfillment is particularly beneficial for small businesses looking to scale. By utilizing FBA, small business owners can leverage Amazon’s infrastructure to manage logistics, allowing them to focus on marketing and sales without the need for extensive warehousing or fulfillment capabilities.

9. What technology is used in Amazon fulfillment centers?

Amazon fulfillment centers utilize advanced technologies such as robotics, automated sorting systems, and sophisticated inventory management software. These technologies streamline the picking and packing process, improve accuracy, and enhance overall efficiency, enabling faster order processing and shipping.

10. What should I consider when choosing a fulfillment center?

When selecting a fulfillment center, consider the following factors:

– Location: Proximity to your customer base can reduce shipping times and costs.

– Service offerings: Look for fulfillment centers that provide a range of services, including returns management and inventory tracking.

– Scalability: Ensure the provider can grow with your business as order volumes increase.

– Technology integration: Check if the fulfillment center seamlessly integrates with your e-commerce platform for real-time inventory management.

Conclusion: Is Outsourcing Fulfillment the Right Move for Your Business?

Assessing the Value of Outsourcing Fulfillment

Outsourcing your fulfillment process can be a game-changer for e-commerce businesses looking to scale operations effectively. One of the primary benefits is time savings. By partnering with a fulfillment center, you delegate the complexities of inventory management, order processing, and shipping, allowing you to focus on what truly matters—growing your business and enhancing customer engagement. This shift can lead to increased productivity and a more strategic allocation of resources.

Scalability is another significant advantage of outsourcing fulfillment. As your business grows, so does the demand for efficient logistics. Fulfillment centers are equipped to handle varying order volumes and can adapt to your needs without the burden of overhead costs associated with expanding your own warehouse space. This flexibility enables you to respond quickly to market changes, seasonal spikes, or new product launches.

Additionally, leveraging the expertise of fulfillment partners can lead to improved efficiency and customer satisfaction. These providers bring specialized knowledge in logistics and technology, ensuring that your orders are processed accurately and shipped promptly. This not only enhances your brand reputation but also cultivates customer loyalty.

However, choosing the right fulfillment partner is crucial for sustained growth. It’s essential to evaluate potential providers based on their location, service offerings, technology integration, and scalability options. A well-aligned partnership can propel your business forward.

Take Action

If you’re contemplating whether outsourcing fulfillment is the right move for your business, start by auditing your current shipping process. Assess your operational bottlenecks, costs, and customer feedback. This analysis will help you determine if a fulfillment partner could enhance your logistics strategy and ultimately support your growth ambitions. Don’t wait—consider how outsourcing could transform your business today.

Important Disclaimer

⚠️ Important Disclaimer

The information in this guide is for educational purposes. Fulfillment services, pricing, and platform features change frequently. Always conduct your own due diligence and consult with providers directly before making business decisions.