How to Ship ‘Delivery From Warehouse’: Costs, Times & Process

Your Complete Guide to delivery from warehouse

Understanding the Challenges of Delivery from Warehouse

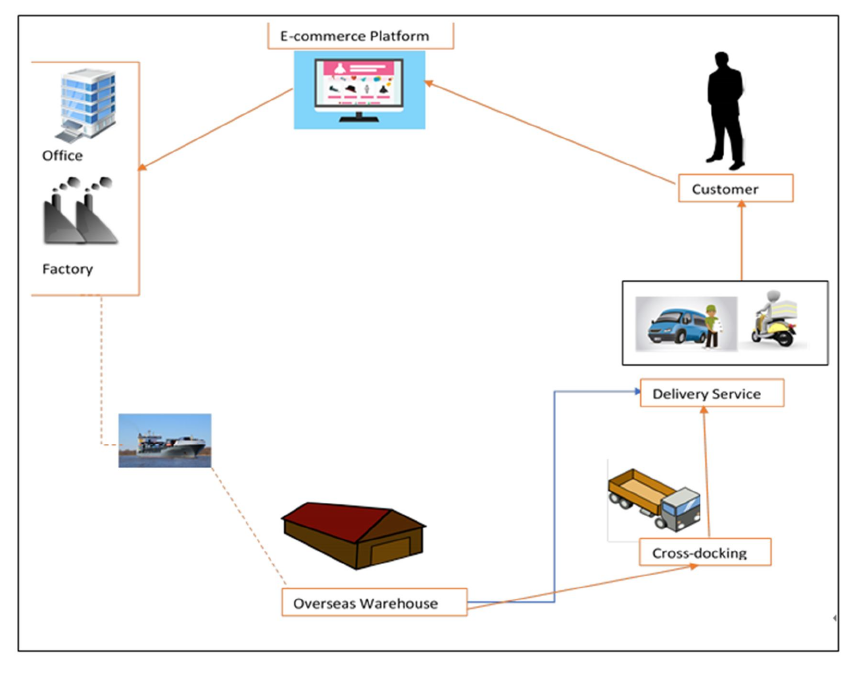

In an increasingly globalized economy, businesses are faced with the pressing challenge of effectively managing their delivery processes from warehouses to customers. The complexities involved in logistics can often seem overwhelming, especially for international shippers, importers, and exporters. These challenges are compounded by the need to balance speed and cost, comply with regulations, and maintain customer satisfaction. One misstep in the delivery process can lead to delays, increased costs, and ultimately, a loss of trust from clients.

As e-commerce continues to flourish, the demand for efficient and reliable delivery solutions has never been greater. Businesses must be equipped with the knowledge and strategies to navigate the myriad of options available for warehouse delivery. This guide aims to provide a comprehensive overview of the crucial aspects of delivery from warehouses, tailored specifically for stakeholders in regions such as the UAE, USA, and Germany.

Key Areas of Focus

This guide will delve into several key areas that are critical for successful warehouse delivery:

-

Shipping Methods: We will explore various shipping methods available, including standard, expedited, and white-glove services, helping you understand which options best suit your business model and customer expectations.

-

Costs: Understanding the cost implications of different shipping methods and how to optimize your logistics budget is vital. We will provide insights into factors influencing shipping costs and how to achieve cost savings without compromising service quality.

-

Transit Times: Speed is often a decisive factor for customer satisfaction. This guide will discuss average transit times associated with different shipping methods and strategies to minimize delays.

-

Customs and Regulations: For international shipments, navigating customs requirements can be daunting. We will outline essential customs procedures and documentation necessary for smooth cross-border deliveries.

-

Risks and Mitigation: Every delivery process carries inherent risks, from product damage to delays. We will identify common risks associated with warehouse deliveries and offer strategies to mitigate them effectively.

Empowering Your Logistics Strategy

By the end of this guide, you will have gained expert knowledge to navigate the complexities of delivery from warehouses efficiently. You will be equipped with practical strategies to optimize your logistics operations, enhance customer satisfaction, and ultimately, drive your business growth. Whether you are a seasoned logistics professional or a business owner new to international shipping, this guide is designed to empower you with the insights needed to streamline your warehouse delivery processes.

Table of Contents

- Your Complete Guide to delivery from warehouse

- Understanding Your Shipping Options: A Detailed Comparison

- Deconstructing the Cost: A Full Pricing Breakdown

- Transit Time Analysis: How Long Will It Take?

- Navigating Customs Clearance: A Step-by-Step Guide

- A Practical Guide to Choosing Your Freight Forwarder

- Incoterms 2020 Explained for Shippers

- Risk Management: Identifying and Mitigating Common Shipping Problems

- Frequently Asked Questions (FAQs) for delivery from warehouse

- Conclusion: Key Takeaways for Successful Shipping

- Important Disclaimer

Understanding Your Shipping Options: A Detailed Comparison

Introduction to Shipping Options from Warehouse

In the global logistics landscape, choosing the right shipping method is crucial for businesses aiming to optimize their supply chain. Whether you are an importer or exporter based in the UAE, USA, or Germany, understanding your shipping options will enable you to make informed decisions that align with your operational needs and customer expectations. This guide provides a detailed comparison of various shipping methods relevant to warehouse delivery, helping you navigate the complexities of freight forwarding.

Comparison Table of Shipping Methods

Here’s a comprehensive comparison of the most common shipping methods used in warehouse delivery:

| Shipping Method | Best For | Speed | Cost Level | Key Advantages | Key Disadvantages |

|---|---|---|---|---|---|

| Sea FCL | Large volumes, bulk goods | Slow (2-6 weeks) | Low | Cost-effective for large shipments; less environmental impact | Longer transit times; port delays |

| Sea LCL | Small volumes, mixed goods | Slow (2-6 weeks) | Moderate | Flexible for smaller shipments; reduced cost | Potential for damage; longer lead times due to consolidation |

| Air | Urgent shipments, high-value goods | Fast (1-5 days) | High | Quick delivery; ideal for perishable or high-value items | Expensive; weight and size limitations |

| Rail | Heavy, bulk commodities | Moderate (1-3 weeks) | Moderate | Eco-friendly; suitable for long distances | Limited availability; slower than air |

| Express | Time-sensitive deliveries | Very fast (1-3 days) | Very high | Guaranteed delivery times; exceptional tracking | Very costly; not suitable for large shipments |

Detailed Breakdown of Each Shipping Method

Sea FCL (Full Container Load)

What it is: Sea FCL shipping involves using an entire container to transport goods, making it ideal for large shipments.

When to Use It: Best for businesses with enough cargo to fill a container (typically 20 or 40 feet).

Pros:

– Cost-effective for large volumes.

– Reduced risk of damage as goods are not mixed with others.

– Lower carbon footprint compared to air freight.

Cons:

– Longer transit times, often taking weeks.

– Vulnerable to port congestion and customs delays.

Sea LCL (Less than Container Load)

What it is: Sea LCL allows multiple shippers to share container space, making it suitable for smaller shipments.

When to Use It: Ideal for companies with less than a full container load.

Pros:

– Economical for small shipments.

– Flexibility in shipping frequency.

Cons:

– Increased risk of damage due to mixed cargo.

– Longer lead times due to consolidation and deconsolidation processes.

Air Freight

What it is: Air freight is the fastest shipping method, transporting goods via commercial airlines.

When to Use It: Best for urgent, high-value, or perishable goods.

Pros:

– Speed: Ideal for time-sensitive deliveries.

– Enhanced security and tracking capabilities.

Cons:

– High costs, making it unsuitable for bulk shipments.

– Weight and size limitations can restrict shipment options.

Rail Freight

What it is: Rail freight involves transporting goods via train, often used for bulk commodities.

When to Use It: Suitable for long-distance transport of heavy goods.

Pros:

– Cost-effective for large, heavy shipments.

– Environmentally friendly compared to road transport.

Cons:

– Limited accessibility compared to trucks.

– Slower than air transport, especially for urgent deliveries.

Express Shipping

What it is: Express shipping guarantees fast delivery, often within 1-3 days.

When to Use It: Best for critical, time-sensitive shipments.

Pros:

– Guaranteed delivery times enhance customer satisfaction.

– Comprehensive tracking capabilities.

Cons:

– Extremely high costs, not practical for large shipments.

– Limited to smaller packages.

Special Considerations

Multimodal Transport

Multimodal transport combines two or more modes of transport to optimize logistics and reduce costs. For instance, you might ship goods via sea to a port and then use rail or road to deliver them to the final destination. This method is particularly beneficial for businesses aiming to reduce delivery times and costs while maximizing flexibility.

Key Advantages:

– Streamlined logistics through integrated shipping solutions.

– Enhanced flexibility to adapt to changing circumstances.

Key Disadvantages:

– Complexity in coordination and potential for delays at transfer points.

Specialized Options

- RoRo (Roll-on/Roll-off): This method is designed for vehicles and heavy machinery. Goods are driven directly onto the vessel, simplifying loading and unloading.

Pros: Quick loading and unloading; ideal for transporting vehicles.

Cons: Limited to wheeled cargo; potential for damage if not secured properly.

- Break Bulk: This involves shipping cargo that cannot fit into standard containers, often used for oversized or heavy items.

Pros: Accommodates large and heavy shipments; versatile.

Cons: Higher handling costs; increased risk of damage during loading and unloading.

Conclusion

Understanding the various shipping options available for delivery from warehouses is essential for businesses engaged in international trade. Each method has its unique advantages and disadvantages, and the choice largely depends on the specific needs of your shipment—volume, urgency, and budget considerations. By leveraging this knowledge, shippers can optimize their logistics strategy, enhance customer satisfaction, and ultimately drive business success.

Deconstructing the Cost: A Full Pricing Breakdown

Understanding the Cost of Delivery from Warehouse

When businesses engage in shipping goods from a warehouse, understanding the associated costs is crucial for maintaining profitability and ensuring competitive pricing. The costs of delivery can be categorized into three primary components: Main Freight, Origin Charges, and Destination Charges. Each of these categories comprises various factors that influence the overall price.

Main Cost Components

Main Freight

Main freight refers to the primary transportation cost associated with moving goods from one location to another. This cost can vary significantly based on several factors:

- Mode of Transport: The choice between sea, air, rail, or road transport affects the cost. For instance, air freight is generally faster but more expensive than sea freight.

- Distance: The longer the distance between the origin and destination, the higher the freight cost.

- Container Size: For ocean freight, the size of the container (e.g., 20ft, 40ft, or LCL—Less than Container Load) plays a critical role in determining costs. Larger containers generally offer lower cost per unit of cargo but may not always be practical for smaller shipments.

- Weight and Volume: Freight charges are often calculated based on the greater of the actual weight or volumetric weight. This means that bulky but lightweight items can incur higher charges.

Origin Charges

Origin charges are fees incurred at the shipping point before the cargo leaves the warehouse. These charges can include:

- Packaging Costs: Proper packaging is essential to protect goods during transit, and costs vary depending on the materials used.

- Loading Fees: Charges for loading the cargo onto the transport vehicle, which can differ based on the complexity of loading operations.

- Documentation Fees: Fees associated with preparing necessary shipping documents, such as bills of lading and customs declarations.

- Customs Clearance: If shipping internationally, customs clearance fees may apply at the origin, which can vary based on the country and type of goods.

Destination Charges

Destination charges are incurred once the goods reach the destination country or location. These may include:

- Unloading Fees: Charges for unloading the cargo from the transport vehicle at the destination warehouse or facility.

- Storage Fees: If the goods are not picked up immediately, storage fees may apply, especially in busy ports or warehouses.

- Delivery Fees: Costs associated with transporting goods from the destination warehouse to the final delivery point.

- Customs Duties and Taxes: Import duties and taxes imposed by the destination country can significantly impact overall costs.

Detailed Cost Factor Analysis

Understanding the cost factors involved in each category can help businesses anticipate and manage their shipping expenses effectively.

Main Freight

- Influencing Factors: Shipping method, distance, container size, weight, and volume.

- Pricing Trends: Market demand and fuel prices can significantly influence freight rates. For example, during peak shipping seasons, rates may increase due to higher demand.

Origin Charges

- Influencing Factors: Type of goods, packaging requirements, complexity of loading, and documentation needs.

- Pricing Trends: Changes in regulations or trade agreements can impact customs clearance costs and documentation fees.

Destination Charges

- Influencing Factors: Location of the delivery, availability of unloading facilities, and storage capacity.

- Pricing Trends: Fluctuations in import duties and taxes can vary based on government policies and trade agreements.

Example Pricing Table

Below is a sample pricing table for shipping costs from China to the USA. Please note that these figures are estimates and can vary widely based on market conditions and specific requirements.

| Shipping Method | Container Size | Estimated Cost (USD) | Notes |

|---|---|---|---|

| Sea Freight | 20ft | $1,500 – $2,500 | Varies by port and season |

| Sea Freight | 40ft | $2,500 – $4,500 | More economical per unit |

| Sea Freight | LCL (1m³) | $150 – $300 | Cost per cubic meter |

| Air Freight | Cost per kg | $5 – $10 | Faster but significantly higher cost |

Disclaimer: The costs listed above are estimates and can vary based on various factors, including shipping routes, demand, and specific carrier rates. It is advisable to obtain quotes from multiple freight forwarders for the most accurate pricing.

How to Reduce Costs

To optimize shipping expenses, businesses can implement several strategies:

-

Consolidate Shipments: Combine smaller shipments into one larger shipment to take advantage of bulk pricing and reduce per-unit costs.

-

Negotiate Rates: Build relationships with multiple freight forwarders and negotiate better rates based on volume and frequency of shipments.

-

Choose the Right Shipping Method: Evaluate the trade-offs between air and sea freight. For non-urgent shipments, sea freight can save significant costs.

-

Optimize Packaging: Use efficient packaging that minimizes weight and volume, potentially lowering freight costs.

-

Plan Ahead: Avoid last-minute shipping, which can incur higher costs. Planning shipments during off-peak seasons can result in lower rates.

-

Utilize Technology: Implement warehouse management systems to track inventory and shipments, leading to better decision-making and cost control.

-

Stay Informed: Keep abreast of changes in shipping regulations, tariffs, and market trends that may affect shipping costs.

By understanding the cost breakdown of delivery from a warehouse and adopting strategic measures to manage expenses, businesses can enhance their supply chain efficiency and improve their bottom line.

Transit Time Analysis: How Long Will It Take?

Factors Influencing Transit Time

Understanding transit times for deliveries from warehouses is essential for international shippers, importers, and exporters. Several variables significantly impact how long it takes for products to reach their destinations. Here are the key factors to consider:

-

Shipping Mode: The choice between sea freight and air freight greatly affects transit times. Air freight is typically faster, taking days rather than weeks, but it comes at a premium cost. Sea freight, while more economical for bulk shipments, can take several weeks due to the longer journey and loading/unloading times.

-

Port Congestion: Major ports worldwide often face congestion, which can delay the loading and unloading of containers. Factors contributing to this congestion include high traffic volumes, labor strikes, or inefficient port operations. It’s crucial to monitor port conditions regularly to anticipate potential delays.

-

Customs Clearance: Customs procedures can be a significant bottleneck in transit times. Inaccurate documentation, inspections, or discrepancies in declarations can lead to delays. Importers should ensure that all paperwork is accurate and compliant with regulations to facilitate a smooth customs process.

-

Routes and Distances: The chosen shipping route can also impact transit time. Direct routes are generally faster, while longer, more complex routes may involve multiple transshipments, adding time to the delivery schedule.

-

Weather Conditions: Adverse weather conditions, such as storms or heavy fog, can disrupt shipping schedules. Companies should always consider seasonal weather patterns when planning shipments, especially for routes that are susceptible to extreme weather events.

-

Last-Mile Delivery: The final leg of delivery from the port or warehouse to the end customer can significantly affect overall transit times. Factors such as local traffic, delivery windows, and the efficiency of the last-mile carrier should be factored into the total delivery time.

Estimated Transit Time Table

The following table provides realistic estimates for transit times from various origins to the USA, specifically for sea and air freight. Note that these estimates are for port-to-port transit and do not include additional time for customs clearance or last-mile delivery.

| Origin | Destination | Sea Freight (Days) | Air Freight (Days) |

|---|---|---|---|

| China | USA | 20-30 | 5-7 |

| Germany | USA | 12-20 | 4-6 |

| UAE | USA | 18-25 | 5-8 |

| USA (East Coast) | USA (West Coast) | 5-7 | 2-3 |

| USA (West Coast) | USA (East Coast) | 5-7 | 2-3 |

Context and Explanation

The estimates provided in the table are based on typical shipping schedules and may vary depending on specific circumstances. For instance, while sea freight from China to the USA might take 20-30 days, unexpected delays due to port congestion or customs issues can extend this timeline significantly.

It’s essential for businesses to plan for potential delays by considering buffer times in their inventory management and customer communication strategies. This includes monitoring shipping routes, being aware of peak seasons that may lead to congestion, and ensuring all customs documentation is accurate and readily available.

Moreover, the last-mile delivery phase, which can vary greatly depending on local conditions, should also be factored into the overall timeline. By understanding these variables and preparing accordingly, businesses can enhance their logistics efficiency and improve customer satisfaction.

Navigating Customs Clearance: A Step-by-Step Guide

Understanding the Customs Clearance Process

Navigating customs clearance can be a daunting task for international shippers, importers, and exporters. This guide provides a structured approach to ensure a smooth delivery from warehouse to destination. Below is a detailed step-by-step workflow, essential documentation, insights on duties and taxes, and common pitfalls to avoid.

The Process Explained

-

Pre-Shipping Preparation

Before initiating the customs clearance process, ensure that all necessary documentation is prepared and that your shipment complies with the destination country’s regulations. This includes determining the appropriate HS Codes for your goods. -

Documentation Submission

Submit all required documents to the customs authorities. This typically includes the Commercial Invoice, Packing List, and any relevant permits or certificates required for specific goods. Ensure that these documents are accurate and complete to avoid delays. -

Customs Declaration

Once the documents are submitted, a customs declaration form must be completed. This form details the nature of the goods, their value, and the intended use. Accuracy is crucial, as discrepancies can lead to fines or seizure of goods. -

Assessment of Duties and Taxes

Customs will review the declaration and calculate any applicable duties and taxes based on the declared value and HS Codes. This assessment is critical in determining the final costs associated with your shipment. -

Payment of Duties and Taxes

Once the assessment is complete, you must pay the required duties and taxes. This payment is necessary to release the shipment for further processing and delivery. Payment methods vary by country, so check local regulations. -

Inspection of Goods

In some cases, customs may require an inspection of the goods. This can occur randomly or due to discrepancies in documentation. Ensure that your shipment is well-organized and accessible for inspection to minimize delays. -

Release of Goods

After successful clearance and payment of all duties and taxes, customs will release your goods. At this point, the shipment can proceed to its final destination, whether that be directly to the customer or through a designated warehouse.

Essential Documentation

Proper documentation is paramount in ensuring a smooth customs clearance process. Below are the key documents you will need:

-

Commercial Invoice: This document lists the goods being shipped, their value, and the terms of sale. It acts as a bill for the goods provided and is used by customs to assess duties and taxes.

-

Packing List: A detailed list of the items in the shipment, including weight and dimensions. This document aids in the inspection process and ensures that all items are accounted for.

-

Bill of Lading (BOL): A legal document between the shipper and carrier that outlines the type, quantity, and destination of the goods. The BOL serves as a receipt for the shipment and is essential for tracking.

-

Customs Declaration Form: A form that provides customs with details about the shipment, including value, classification, and origin. Accurate completion is critical to avoid issues.

-

Certificates and Permits: Depending on the nature of the goods, additional documentation such as certificates of origin, phytosanitary certificates, or export licenses may be required.

Duties, Taxes, and HS Codes

HS Codes (Harmonized System Codes) are internationally standardized numbers that classify products for customs purposes. They determine the duties and taxes applicable to your shipment. Each product category has a specific HS Code, which can be found through the customs authority or trade databases.

Duties and Taxes Calculation: Duties are typically calculated as a percentage of the declared value of the goods, while taxes may include VAT or sales tax depending on the destination country. It’s crucial to ensure the declared value is accurate to avoid overpayment or penalties.

Common Problems & Solutions

-

Incomplete Documentation

Problem: Missing or incorrect documents can lead to delays or rejection of shipments.

Solution: Create a checklist of required documents and verify completeness before submission. Double-check for accuracy in all information. -

Misclassification of Goods

Problem: Incorrect HS Codes can result in improper duty assessments or fines.

Solution: Research and confirm the correct HS Codes for your products. Consult with customs brokers or trade specialists if necessary. -

Payment Delays

Problem: Delays in paying duties and taxes can hold up shipments.

Solution: Familiarize yourself with the payment process and ensure funds are available. Use electronic payment methods where possible for efficiency. -

Customs Inspections

Problem: Random inspections can delay the delivery process.

Solution: Prepare shipments for inspection by ensuring they are well-organized and easy to access. Maintain clear and complete records to facilitate the inspection process. -

Regulatory Changes

Problem: Changes in customs regulations can impact clearance processes.

Solution: Stay informed about current regulations in the destination country. Subscribe to trade updates or work with a customs broker to receive timely information.

Conclusion

Successfully navigating customs clearance is essential for international shipping. By following this step-by-step guide, ensuring all documentation is in order, understanding the implications of duties and HS Codes, and being aware of common pitfalls, businesses can streamline their operations and enhance their global shipping strategies. Proper preparation not only expedites the delivery process but also strengthens relationships with customers and suppliers alike.

A Practical Guide to Choosing Your Freight Forwarder

Understanding the Role of a Freight Forwarder in Warehouse Deliveries

When it comes to efficiently delivering goods from a warehouse to their final destination, choosing the right freight forwarder is crucial. A freight forwarder acts as an intermediary between the shipper and various transportation services, managing the logistics of transporting goods internationally or domestically. The right partner can streamline your supply chain, reduce costs, and enhance customer satisfaction. Here’s a practical guide to help you select the ideal freight forwarder for your warehouse delivery needs.

Key Qualities to Look for in a Freight Forwarder

- Experience and Expertise

-

Look for a freight forwarder with a proven track record in your specific industry. Experience in handling goods similar to yours can help navigate potential pitfalls and ensure compliance with regulations.

-

Global Network

-

A robust network of agents and partners across various regions is essential. This enables the freight forwarder to provide flexible and efficient shipping options, ensuring timely deliveries regardless of the destination.

-

Licensing and Compliance

-

Ensure the freight forwarder holds the necessary licenses and certifications. This includes compliance with international shipping regulations, customs brokerage licenses, and insurance coverage to protect your cargo.

-

Technology Integration

-

Modern freight forwarders utilize advanced technology for tracking shipments, inventory management, and communication. This transparency can significantly enhance your operational efficiency and provide real-time updates on your shipments.

-

Communication Skills

-

Effective communication is vital. Your freight forwarder should provide clear and timely information regarding shipping schedules, potential delays, and any issues that arise during transport.

-

Customer Service

- A freight forwarder should prioritize customer service. Look for a company that is responsive and willing to provide personalized solutions tailored to your specific needs.

Sourcing Checklist for Selecting a Freight Forwarder

To make an informed decision, follow this actionable checklist:

- Define Your Needs

-

Clearly outline what you require from a freight forwarder. Consider factors such as shipment size, frequency, destinations, and specific handling needs.

-

Conduct Research

-

Explore potential freight forwarders through online resources, industry forums, and recommendations. Pay attention to their specialization and service offerings.

-

Request Quotes

-

Reach out to multiple freight forwarders and request quotes. Ensure that the quotes are comprehensive, covering all potential costs such as freight rates, customs duties, and additional fees.

-

Ask Questions

-

Don’t hesitate to ask detailed questions. Inquire about their experience, network, technology, and how they handle specific challenges in the shipping process.

-

Check References

- Ask for references from previous clients, particularly those in your industry. This will give you insight into their reliability and service quality.

Red Flags to Watch Out For

While evaluating potential freight forwarders, keep an eye out for warning signs that may indicate potential issues:

- Lack of Transparency

-

If a freight forwarder is unwilling to provide detailed quotes or information about their services, it may signal a lack of professionalism or hidden costs.

-

Poor Communication

-

Delayed responses or vague answers to your questions can indicate poor customer service. Effective communication is essential for a successful partnership.

-

Insufficient Experience

-

A freight forwarder without relevant experience in your industry may struggle with the specific requirements and challenges of your shipments.

-

Negative Reviews

-

Research online reviews and testimonials. Consistent negative feedback about delivery times, service quality, or customer support is a significant red flag.

-

Unlicensed Operations

-

Ensure that the freight forwarder is properly licensed and adheres to legal regulations. Unlicensed operators may expose you to significant risks.

-

High Turnover Rates

- If a freight forwarder frequently changes staff or has a high turnover rate, it could affect the quality of service and continuity of operations.

Conclusion

Choosing the right freight forwarder for your warehouse deliveries is a critical step in optimizing your logistics operations. By focusing on key qualities, following a systematic sourcing checklist, and being aware of potential red flags, you can make an informed decision that enhances your supply chain efficiency. A reliable freight forwarder not only ensures the safe and timely delivery of goods but also contributes to improved customer satisfaction and business growth.

Incoterms 2020 Explained for Shippers

Understanding Incoterms for Global Shipping

In the realm of international trade, clarity and mutual understanding between buyers and sellers are paramount. Incoterms, or International Commercial Terms, provide a standardized set of rules that define the responsibilities of parties involved in the shipping and delivery process. Established by the International Chamber of Commerce (ICC), these terms help delineate who is responsible for various aspects of shipping, including transportation costs, risk management, and customs duties. The latest version, Incoterms 2020, outlines critical changes and clarifications that are essential for shippers, importers, and exporters to grasp, especially in a global marketplace that spans regions like the UAE, USA, and Germany.

Key Incoterms Table

| Incoterm | Who Pays for Transport? | Where Risk Transfers? | Best for |

|---|---|---|---|

| EXW | Buyer | Seller’s premises | Buyers wanting minimal responsibility |

| FOB | Seller | Ship’s rail | Sellers looking to control shipping until the port |

| CIF | Seller | Destination port | Buyers wanting cost certainty and insurance |

| DDP | Seller | Delivery location | Buyers wanting maximum service with no hassle |

Detailed Explanation of Common Incoterms

EXW (Ex Works)

Under the EXW term, the seller’s responsibility is minimal. They merely need to make the goods available at their premises (or another named place) for the buyer to collect. The buyer assumes all risks and costs associated with transporting the goods from that point onward. For instance, if a furniture manufacturer in Germany sells products to a retailer in the UAE under EXW terms, the manufacturer simply has to make the furniture available at their factory. The UAE retailer must then arrange for all subsequent transport, including export customs clearance, freight, and insurance.

FOB (Free On Board)

FOB is a more seller-centric term that requires the seller to cover all costs and risks until the goods are loaded onto the vessel at the port of shipment. Once loaded, the risk transfers to the buyer. This term is particularly beneficial for sellers who want to maintain control over the shipping process until the point of loading. For example, a US exporter of electronic goods shipping to a buyer in Germany would be responsible for all costs up to the point the goods are loaded onto the ship at a US port. After that, the German buyer takes on risk and responsibility.

CIF (Cost, Insurance, and Freight)

CIF goes a step further than FOB by requiring the seller to pay for costs, insurance, and freight to bring the goods to the destination port. This term provides buyers with added security, as they do not have to worry about insuring the goods during transit. For instance, if a furniture supplier in the UAE sells to a retailer in Germany under CIF terms, the supplier will handle the shipping and insurance costs until the goods reach the German port, ensuring the buyer has peace of mind regarding potential damages during transit.

DDP (Delivered Duty Paid)

DDP represents the seller’s maximum responsibility, as they take on all risks and costs associated with delivering the goods to the buyer’s specified location, including import duties and taxes. This term is ideal for buyers who prefer a hassle-free experience. For example, if a German company imports machinery from the USA under DDP terms, the American seller is responsible for everything—transportation, customs clearance, and delivery to the German buyer’s warehouse, ensuring a seamless transaction with no unexpected costs for the buyer.

Conclusion

Understanding Incoterms 2020 is crucial for shippers, importers, and exporters aiming for efficient international transactions. By clarifying responsibilities and risks, these terms not only streamline logistics but also foster trust and transparency in global trade. When navigating delivery from warehouse operations, selecting the appropriate Incoterm can significantly impact costs, risk management, and overall customer satisfaction.

Risk Management: Identifying and Mitigating Common Shipping Problems

Introduction

In the realm of international shipping and logistics, proactive risk management is essential for ensuring a seamless delivery process from warehouse to customer. Effective risk management not only protects your assets but also enhances customer satisfaction, builds brand loyalty, and ultimately contributes to your bottom line. By identifying potential issues before they escalate, businesses can implement strategies that mitigate risks, streamline operations, and maintain a competitive edge in the global marketplace.

Risk Analysis Table

Understanding the potential risks associated with shipping is the first step in developing effective mitigation strategies. Below is a comprehensive risk analysis table that outlines some common shipping problems, their potential impacts, and practical mitigation strategies.

| Potential Risk | Impact | Mitigation Strategy |

|---|---|---|

| Cargo Damage | Financial loss, customer dissatisfaction, and increased returns. | Utilize high-quality packing materials, train staff on proper handling techniques, and conduct regular inspections. |

| Delays | Missed deadlines, increased operational costs, and dissatisfied customers. | Implement robust tracking systems, maintain clear communication with carriers, and build flexibility into delivery timelines. |

| Customs Holds | Extended delivery times, potential fines, and inventory stagnation. | Ensure all documentation is accurate and complete, work with experienced customs brokers, and stay updated on regulatory changes. |

| Theft or Loss | Financial loss and potential harm to reputation. | Invest in secure storage solutions, implement GPS tracking for high-value shipments, and conduct background checks on delivery personnel. |

| Regulatory Compliance | Fines, shipment delays, and damaged reputation. | Stay informed about local and international shipping regulations, conduct regular audits, and provide compliance training for staff. |

| Inaccurate Deliveries | Increased costs due to re-delivery, wasted time, and customer frustration. | Use technology to verify delivery addresses, maintain accurate inventory records, and ensure clear labeling of packages. |

Cargo Insurance Explained

What It Covers

Cargo insurance is a vital component of risk management in shipping, providing financial protection against various types of loss or damage to goods during transit. It typically covers:

- Physical Damage: Protection against loss or damage due to accidents, theft, fire, or natural disasters.

- Theft: Coverage for loss of goods due to criminal activities.

- General Average: A principle in maritime law that allows for shared losses among all parties in a maritime venture when cargo is sacrificed for the safety of the ship.

Types of Cargo Insurance

There are several types of cargo insurance policies available, including:

- All-Risk Insurance: This comprehensive policy covers all types of risks unless specifically excluded.

- Named Perils Insurance: This policy only covers risks explicitly listed in the policy, such as fire, theft, or collision.

- Warehouse-to-Warehouse Coverage: This type of policy extends coverage from the time goods are loaded at the origin warehouse until they are unloaded at the destination warehouse.

Why It’s Essential

Investing in cargo insurance is crucial for several reasons:

- Financial Protection: It mitigates the financial impact of unforeseen events that could result in loss or damage to goods.

- Peace of Mind: Knowing that your goods are insured allows businesses to focus on core operations without the constant worry of potential losses.

- Customer Confidence: Providing assurance that products are insured can enhance customer trust and satisfaction, as clients feel more secure in their purchases.

Conclusion

In the ever-evolving landscape of international shipping, effective risk management is not just a safety net; it is a strategic approach that can define a business’s success. By proactively identifying potential risks, implementing robust mitigation strategies, and investing in cargo insurance, businesses can safeguard their assets, enhance customer satisfaction, and foster long-term growth. The complexities of shipping may present challenges, but with careful planning and execution, they can be transformed into opportunities for success.

Frequently Asked Questions (FAQs) for delivery from warehouse

1. What is warehouse-to-door delivery, and how does it work?

Warehouse-to-door delivery refers to the logistics process where goods are transported directly from a warehouse to the customer’s designated location. This service typically involves picking up the items from the warehouse, handling any necessary packaging or assembly, and then delivering them straight to the customer. Advanced tracking systems enable real-time updates, ensuring both the shipper and customer can monitor the delivery process.

2. What are the benefits of using a white-glove delivery service?

White-glove delivery services offer premium handling for sensitive or high-value items, such as furniture or electronics. Benefits include careful handling, setup, and installation at the delivery site, as well as the removal of packaging materials. This service ensures a high level of customer satisfaction and is particularly beneficial for businesses that prioritize customer experience.

3. How can I track my delivery from the warehouse?

Most logistics providers offer tracking systems that allow you to monitor your shipment in real-time. You can typically track your delivery using a unique tracking number provided at the time of shipment. This number can be entered on the logistics provider’s website or app to receive updates on the delivery status, estimated arrival time, and any delays.

4. What is the difference between a Bill of Lading (BOL) and an Air Waybill (AWB)?

A Bill of Lading (BOL) is a legal document between the shipper and carrier that outlines the details of the shipment, including type, quantity, and destination of the goods. It is primarily used for ground transportation. An Air Waybill (AWB), on the other hand, is a document used for air freight that serves as a receipt for the goods and a contract for carriage. While both documents serve similar purposes, they are specific to their modes of transportation.

5. What factors determine chargeable weight in shipping?

Chargeable weight is calculated based on both the actual weight and the dimensional weight of a shipment. The carrier will charge based on the greater of the two. Dimensional weight is determined by the size of the package (length x width x height) divided by a specific divisor set by the carrier. Understanding chargeable weight helps businesses manage shipping costs more effectively.

6. What are customs bonds, and why are they necessary for international shipping?

Customs bonds are agreements between the shipper and customs authorities that ensure compliance with regulations and payment of duties. They are required for importing goods into a country and can serve to cover potential duties, taxes, and penalties. Having a customs bond is essential for smooth customs clearance and to avoid delays in delivery.

7. How can I ensure my delivery is on time?

To enhance the likelihood of timely delivery, it is crucial to choose a reliable logistics provider known for their punctuality. Additionally, providing accurate shipping information, being flexible with delivery times, and utilizing technology for tracking can help ensure the delivery process is efficient. Establishing good communication with the carrier can also facilitate timely updates regarding any potential delays.

8. What should I do if my delivery is delayed?

If your delivery is delayed, first check the tracking information provided by your logistics provider. If the information is unclear, contact their customer service for updates. They can provide insight into the cause of the delay and an estimated time of arrival. Keeping the lines of communication open will help manage expectations and facilitate solutions.

9. Are there specific packaging requirements for warehouse deliveries?

Yes, packaging requirements may vary based on the type of goods being shipped and the logistics provider’s policies. Generally, items should be securely packaged to prevent damage during transit. For fragile items, additional cushioning and protective materials are recommended. It’s advisable to consult with your logistics provider for their specific packaging guidelines to ensure compliance and minimize damage risks.

10. What are the costs involved in delivery from a warehouse?

Costs associated with warehouse delivery can include shipping fees, handling charges, insurance, and any additional services such as white-glove delivery or special packaging. It’s important to get a detailed quote from your logistics provider, which should outline all potential charges to avoid unexpected expenses. Understanding these costs helps businesses budget effectively for their logistics needs.

Conclusion: Key Takeaways for Successful Shipping

Strategic Planning is Essential

Successful shipping from warehouse to customer hinges on meticulous planning. Understand your supply chain dynamics and forecast demand accurately to ensure that inventory levels align with customer expectations. This not only enhances operational efficiency but also minimizes delays, ultimately leading to improved customer satisfaction. Regularly assess your shipping processes and adjust strategies based on market trends and consumer behavior to stay ahead of the competition.

Choosing the Right Partners

Selecting reliable logistics partners is crucial for smooth operations. Collaborate with freight forwarders and last-mile delivery specialists who have a proven track record in your industry. Whether you are in the UAE, USA, or Germany, a partner that understands local regulations and market nuances can significantly streamline your shipping processes. Evaluate their technology capabilities, as real-time tracking and communication systems are vital for maintaining transparency with your customers.

Cost Management and Optimization

Cost control should be a priority when planning your shipping strategy. Analyze shipping costs and explore multiple carrier options to ensure you are getting the best rates without compromising service quality. Leveraging technology can help identify cost-saving opportunities, such as consolidating shipments or optimizing delivery routes. A well-managed logistics strategy not only reduces expenses but also enhances your bottom line.

Take Action Today

In the evolving landscape of global shipping, staying competitive requires proactive measures. Begin by reassessing your shipping strategy, exploring new partnerships, and investing in technology that supports efficiency and transparency. The path to successful shipping is paved with informed decisions and strategic planning. Embrace these principles today to elevate your logistics operations and satisfy your customers’ demands effectively. Your journey to enhanced shipping begins now!

Important Disclaimer

⚠️ Important Disclaimer

The information in this guide is for educational purposes only and does not constitute professional logistics advice. Rates, times, and regulations change frequently. Always consult with a qualified freight forwarder for your specific needs.